Description

The QE95 series detectors are engineered to provide comprehensive solutions for energy measurement across various light sources. Featuring a modular design, these detectors come equipped with two distinct cooling modules, enhancing their power handling capabilities. A standout feature is their extra-large effective aperture of 95 mm Ø, ensuring compatibility with a broad spectrum of beam sizes.

Gentec-EO - Energy Detector - QE95LP-H-MB

Specifications

| Max Measurable Energy: | 70000 mJ |

|---|---|

| Max Repetition Rate: | 40 Hz |

| Effective Aperture: | 95 mm |

| Spectral Range: | 0.19 – 20 um |

| Damage Threshold (Max Power): | 40 W |

Features

- Modular Design: Offers two cooling modules to accommodate different power levels, allowing for customizable setups.

- Extra Large Aperture: The 95 mm Ø aperture caters to a wide range of beam diameters, making it versatile for diverse applications.

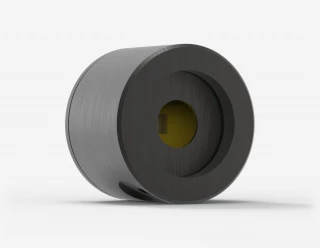

- QED Attenuator: Enhances the detector's range, allowing it to measure up to 5X higher energies. It is optionally calibrated for specific wavelengths between 532 & 1064 nm or for a single wavelength, adding to its adaptability.

- Low Noise Level: Ensures precise measurements with a noise level of just 15 μJ for the MB coating.

- Smart Interface: Embedded with all necessary calibration data, facilitating ease of integration and use.

- Comprehensive Measurement Capability: Capable of measuring energies from 15 μJ to 250 J, with specific models designed for long pulse durations.

Applications

- Laser Beam Profiling and Analysis: Essential for the detailed analysis of laser beam characteristics, including energy distribution, ensuring optimal beam quality for various applications.

- Laser System Calibration: Used in calibrating laser systems to verify and adjust their output, ensuring that they operate within specified parameters for precision applications.

- Material Testing: Key in evaluating material responses to different energy levels, especially in fields like material science and engineering, where understanding material behavior under laser exposure is crucial.

- Medical Device Testing: Plays a critical role in the calibration and testing of medical laser devices, ensuring they deliver the correct energy levels for treatments such as laser surgery and dermatology.

- Photonics Research: Supports advanced research in photonics, including the study of light behavior and the development of new light-based technologies.

- Industrial Processing and Manufacturing: Used in monitoring and controlling laser systems in industrial applications like cutting, welding, and engraving, where precise energy output is vital for quality and efficiency.

- Educational and Training Institutes: Serves as a teaching tool in educational settings, allowing students and researchers to gain hands-on experience with laser measurement and analysis.

- Quality Control in Manufacturing: Ensures that products involving laser technology meet stringent quality standards by accurately measuring the energy output of laser systems.

Frequently Asked Questions

What is the maximum pulse energy that the QE95LP-H-MB energy detector can measure?

The QE95LP-H-MB energy detector can measure pulse energy of up to 250J with an attenuator and 70J without an attenuator.

Is it possible to increase the power capability of the detector?

Yes, the detector has a modular concept that allows you to increase the power capability with two different cooling modules.

What is the effective aperture of the detector?

The detector has an effective aperture of 95 mm Ø.

Is there an attenuator available for the QE95LP-H-MB energy detector?

Yes, the QE95LP-H-MB energy detector has a QED attenuator available that allows you to measure up to 5X higher energies. It is available with optional calibration for all wavelengths between 532 & 1064 nm or for a single wavelength.

What is the noise level of the MB coating?

The MB coating has a low noise level of 15 μJ.

What is the purpose of the test target included with the MB models?

The test target included with the MB models is used for calibration purposes.

What are the applications of the QE95LP-H-MB energy detector?

The QE95LP-H-MB energy detector is used for pulsed high power laser energy measurements in a wide spectral range of 190nm - 20um (without attenuator) and for spectroscopy.

Similar Products

IS50A-1KW-RMT High-Power Joulemeter: 1kW Laser Energy Measurement with NIST-Traceable Calibration & Resistant Coating

Gentec-EO

Gentec-EO QE195LP-S-MB: 195mm High-Precision Laser Energy Detector

Gentec-EO

PE3B-IN-D0 Photodiode Detector

Gentec-EO

PE3B-SI-D0 Photodiode Detector

Gentec-EO

PE5B-GE-D0 - Photodiode Detector for Laser Energy Measurement

Gentec-EO

Gentec-EO Pyroelectric Detector QE65ELP-H-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65ELP-S-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-H-MB-QED-D0

Gentec-EO

Gentec-EO QE65LP-H-MB-D0 Pyroelectric Detector

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-S-MB-QED-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE65LP-S-MB-D0

Gentec-EO

Gentec-EO Pyroelectric Detector QE25HR-H-MB-QED-D0

Gentec-EO

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle