Description

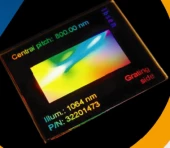

The Fused Silica Transmission Grating from Ibsen is a cutting-edge solution designed to meet the rigorous demands of modern femtosecond laser systems. As these systems advance to higher energy levels, the need for pulse compression gratings with exceptional energy and power handling capabilities has become paramount. Ibsen's gratings are crafted from 100% fused silica, providing an unmatched energy/power damage threshold while maintaining high-efficiency spectral performance and minimal wavefront distortion.

Ibsen's pulse compression gratings leverage the company's world-leading expertise in fused silica transmission grating technology. This expertise is complemented by state-of-the-art interferometric patterning and advanced reactive ion etching processes, ensuring superior quality and performance. While Ibsen offers custom and OEM manufacturing options, an increasing number of gratings are available from stock, such as the model described in this overview.

The model PCG-3039.5-450-810 is meticulously engineered to deliver optimal performance at a nominal wavelength of 450 nm with a grating resolution of 3039.5 lines per millimeter. This grating exemplifies Ibsen's commitment to providing high-performance solutions that are both environmentally and thermally stable. With a high diffraction efficiency and low transmitted wavefront distortion, these gratings are ideal for applications requiring precise light manipulation.

Ibsen's dedication to quality is evident in their manufacturing process, which takes place in a Class 10 cleanroom environment. Utilizing two-beam interferometry and reactive ion etching, each grating is crafted to meet stringent specifications. The back-side of the grating is treated with a high-power dielectric anti-reflective coating, further enhancing its performance and durability.

As a trusted partner, Ibsen works closely with customers throughout the design and manufacturing process, from initial concept to volume production of OEM gratings. This collaborative approach ensures that each product not only meets but exceeds the specific needs of the application.

Pulse Compression Grating

Specifications

| Groove Density: | 3039.5 l/mm |

|---|---|

| Center Wavelength: | 450 nm |

| Material: | Fused silica and high-power, dielectric AR coating materials |

| Grating Area: | 20 mm x 20 mm |

| Substrate Size: | 22 mm x 22 mm x 1 mm |

| Dispersion At 450 Nm: | 0.24 deg/nm |

| Nominal Wavelength: | 450 nm |

| Angle Of Incidence (AOI): | Littrow (43 deg) |

| Diffraction Efficiency (TE): | >92% |

| Back-side AR Coating: | High power, dielectric AR coating applied |

| Production Technology: | 2-beam Interferometry and Reactive Ion Etch, Class 10 cleanroom environment |

Features

- Unbeatable Energy/Power Damage Threshold: Designed to handle high energy levels, perfect for advanced femtosecond laser systems.

- High-Efficiency Spectral Performance: Offers high diffraction efficiency for optimal performance.

- Environmentally and Thermally Stable: Ensures consistent performance under varying environmental conditions.

- Low Wavefront Distortion: Maintains high optical quality with minimal distortion.

- High Tolerance to Incidence Angle: Flexible design accommodates various angles of incidence. Back-side AR Coating: High power, dielectric AR coating applied

- Manufacturing Excellence: Produced using advanced interferometric patterning and reactive ion etching technologies in a Class 10 cleanroom environment.

- Custom/OEM Availability: While custom options are available, many gratings are also in stock for immediate delivery.

Applications

- Femtosecond Laser Pulse Compression: Optimized for compressing high-energy ultrafast laser pulses with minimal distortion.

- High-Power Laser Systems: Ideal for systems requiring high damage threshold gratings.

- Spectroscopy and Microscopy: Suitable for advanced laser-based analytical systems.

- Ultrafast Laser Research: Supports R&D requiring precise pulse compression components.

- OEM Laser Manufacturing: Integrates into commercial laser products requiring reliable pulse compression performance.

Frequently Asked Questions

What is a pulse compression grating?

What material is used to manufacture Ibsen's pulse compression gratings?

What are the benefits of using Ibsen's pulse compression gratings?

What applications are pulse compression gratings used for?

Can Ibsen manufacture custom pulse compression gratings?

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle