Description

The ion beam sputtering (IBS) coating process is used in highly demanding coatings. Like no other technology, the process parameters, auch as energy input, layer growth rate, and level of oxidation, can be exactly and independently set. The desired layer structures can be produced very precisely and with a high reproducibility.

IBS Coating

Laser Components USA, Inc.

Specifications

| Coating Layers: | Multi-layer |

|---|---|

| Angle Of Incidence (AOI): | Not Specified |

| Wavelength Range: | 260 – 3000 nm |

Features

- Dreft-free layers

- Low-dispersion coatings

- "Cold coatings\" on temperature-sensitive materials

- Extremely high degree of reflection R>99.99%

- Coatings with varying indices of refraction (so-called mixed layers) for very high damage thresholds

- Dichroic mirrors with wide transmission bands that have a consistently hight transmission

- Chirped mirrors for fs applications

- Very broadband mirrors and AR coatings

- Narrowband coatings for high power compatible filters

- Wide wavelength range from 260nm to 3000nm

Frequently Asked Questions

What is the IBS coating process used for?

The IBS coating process is used for highly demanding coatings.

What are the features of the IBS coating?

The features of the IBS coating include Dreft-free layers, low-dispersion coatings, "cold coatings" on temperature-sensitive materials, extremely high degree of reflection R>99.99%, coatings with varying indices of refraction, dichroic mirrors with wide transmission bands, chirped mirrors for fs applications, very broadband mirrors and AR coatings, narrowband coatings for high power compatible filters, and a wide wavelength range from 260nm to 3000nm.

What are the benefits of the IBS coating process?

The benefits of the IBS coating process include the ability to precisely and independently set process parameters, produce desired layer structures with high reproducibility, and create coatings with a high degree of reflection and varying indices of refraction.

What materials can the IBS coating be applied to?

The IBS coating can be applied to temperature-sensitive materials and can produce coatings with a high damage threshold.

What is the transmission range of the dichroic mirrors produced by the IBS coating process?

The dichroic mirrors produced by the IBS coating process have a wide transmission band and consistently high transmission.

Similar Products

AR BBAR DLC Coating

Henan UM Optics Ltd

Broadband AR Coated Window M185-950-2AR-2D-FL 185-950nm (2.0” Diameter)

Teledyne Acton Optics

Broadband AR Coated Window M185-950-2AR-1D-FL 185-950nm (1.0” Diameter)

Teledyne Acton Optics

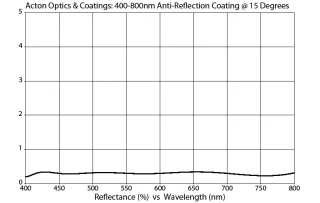

Broadband AR Coated Window M400-800-2AR-2D-FL 400-800nm (2.0” Diameter)

Teledyne Acton Optics

Broadband AR Coated Window M400-800-2AR-1D-FL 400-800nm (1.0” Diameter)

Teledyne Acton Optics

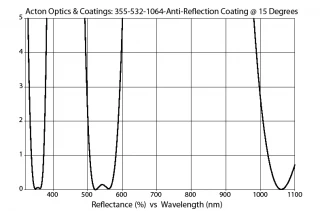

Broadband AR Coated Window M355-532-1064-2D-FL 355-532-1064nm (2.0” Diameter)

Teledyne Acton Optics

Broadband AR Coated Window M355-532-1064-1D-FL 355-532-1064nm (1.0” Diameter)

Teledyne Acton Optics

ITO Coated Optical Window - High Transparency and Conductivity

Sinoptix

Thank You!

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle