Ceramic Laser Pump Cavity Ceramic Reflector

Description

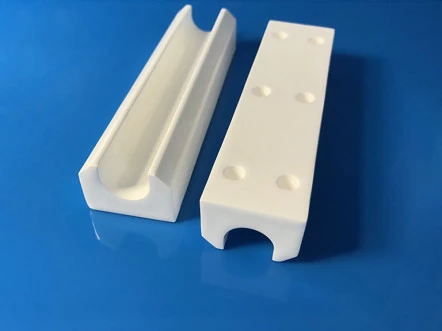

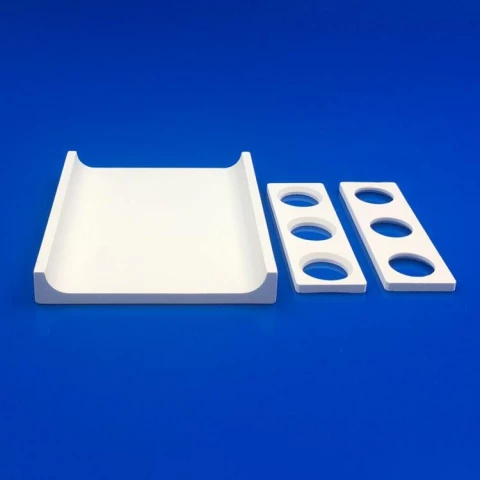

Innovacera Ceramic laser reflectors are high reflectance cavities used in solid state and CO2 laser systems. It is made of high purity 99% porous alumina ceramic and sintered at high temperatures to achieve a controlled porosity.

Our range of custom ceramic reflectors offers significant advantages and improvements over those made with materials such as metal and polymer, it works particularly well in Ruby and Nd:YAG laser pumping chambers and is used extensively for long-life laser reflectors.

Ceramic Laser Pump Cavity Ceramic Reflector

Specifications |

|

|---|---|

| Material: | Ceramic |

| Type Of Ceramic: | Glazed, Unglazed |

| Component Type: | Reflectors |

| Density: | 3.1Mg/m3 |

Features

1. Dimensional tolerance in height direction can achieve tolerance ≤1.0mm, other dimensional tolerances can reach ≤0.5mm

2. The surface is fully glazed to achieve maximum reflectivity and easy to clean

3. The reflectivity reaches 97% at the wavelength of 600-1000nm

4. The reflectivity exceeds 95% in the wavelength range of 380-1100nm

5. The body has proper porous and high strength characteristics

Applications

- Pumping chambers for flash lamp and continuous-wave lasers using media such as Nd: YAG lasers, Alexandrite

— low to high power, single or multiple lamp designs used for welding, cutting, marking and in medical lasers. YAG lasers, Alexandrite

— low to high power, single or multiple lamp designs used for welding, cutting, marking and in medical lasers.

- Layered and segmented pumping chambers for diode-pumped lasers

- Intense Pulse Light (IPL) applications for cosmetic surgery IPL) applications for cosmetic surgery

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2020

Frequently Asked Questions

Ceramic Laser Pump Cavity Ceramic Reflectors offer significant advantages and improvements over those made with materials such as metal and polymer. It works particularly well in Ruby and Nd:YAG laser pumping chambers and is used extensively for long-life laser reflectors.

The applications of Ceramic Laser Pump Cavity Ceramic Reflectors are pumping chambers for flash lamp and continuous-wave lasers using media such as Nd: YAG lasers, Alexandrite — low to high power, single or multiple lamp designs used for welding, cutting, marking and in medical lasers, layered and segmented pumping chambers for diode-pumped lasers, and intense pulse light (IPL) applications for cosmetic surgery.

The features of Ceramic Laser Pump Cavity Ceramic Reflectors are dimensional tolerance in height direction can achieve tolerance ≤1.0mm, other dimensional tolerances can reach ≤0.5mm, the surface is fully glazed to achieve maximum reflectivity and easy to clean, the reflectivity reaches 97% at the wavelength of 600-1000nm, the reflectivity exceeds 95% in the wavelength range of 380-1100nm, and the body has proper porous and high strength characteristics.

The physical properties of Ceramic Laser Pump Cavity Ceramic Reflectors are color: White, bulk density (fired), Mg/m3:3.1, porosity (apparent), % nominal:22, flexural strength (ASTM C1161, 3-point), MPa :170, and thermal expansion coefficient 200-500C, 10-6/C 7.9 200-1000C, 10-6/C 9.0.

It is a high reflectance cavity used in solid state and CO2 laser systems made of high purity 99% porous alumina ceramic and sintered at high temperatures to achieve a controlled porosity.