Description

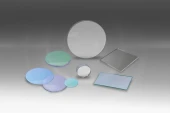

New polishing equipment enables exceptional surface finish of optical substrates.

Precision Glass & Optics (PG&O), a global leader in optical manufacturing and thin film coatings based on single-sided polishing for nearly 40 years, announces new double-sided polishing (DSP) capabilities. The cutting-edge technology of the newly installed PR Hoffman 5400 double-sided polishing machine allows the company to polish parts in days, rather than weeks, providing customers with the highest quality products in the shortest possible time to meet the fast-paced demands of today’s market with unprecedented efficiency.

The PR Hoffman 5400 DSP ensures sub-second parallelism and exceptional fractional transmitted wavefront error, for production of high-volume optics with unrivaled consistency, precision, exceptional dimensional accuracy and surface finishes on substrates such as Fused Silica, BK-7, and other materials. The machine balances internal stresses within materials, minimizing the risks of warping or deformation for optimal consistency and repeatability on substrates up to 250 mm diameter.

Double-Sided Polishing for High-Volume, High-Precision Optical Components

Specifications

| Max Diameter: | Not Specified |

|---|---|

| Radius Range: | 25 – 250 mm |

| Positioning And Repeat Accuracy: | Not Specified |

| Thicknesses: | 0.5 mm to 25 mm |

Features

Double-Sided Polishing (DSP) Optics enables:

- High volume production

- Substantial reductions in lead times and production costs

- Excellent transmitted wavefront, parallelism, and thickness control

Applications

- Semiconductor wafers

- Medical devices

- Laser systems

- Aerospace parts

- Mission critical tasks

Your inquiry has been received.

Create an account by adding a password

Why create an account?

- Auto-complete inquiry forms

- View and manage all your past messages

- Save products to your favorites

- Close your account anytime — no hassle