Innovacera Metallized Ceramic Substrate

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2020

Description

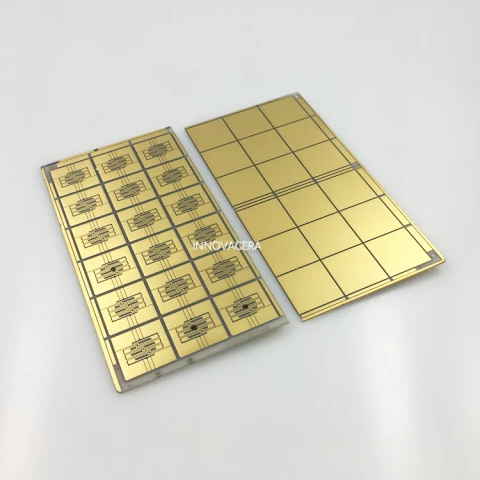

Innovacera manufactures High-performance metalized substrates and photodiode sub-mounts, circuits, and spacers to customer specifications.

Innovacera Metallized Ceramic Substrate

Specifications |

|

|---|---|

| Substrate Size: | 45 – 45 mm |

| Base Vacuum: | 10 Torr |

| Max Substrate Temperature: | 450 degC |

| Process Type: | Other |

Applications

The micro-devices that can be made with ceramic film integrated circuits include: filters, couplers, power dividers, microstrip transmission lines, high-power switch circuits, circulators, isolators, resistors, attenuators, and other custom-made devices as requested by the customer.

Frequently Asked Questions

Alumian, Aluminum nitride, beryllium oxide. Aluminum nitride and beryllium oxide are used for high-power applications; Aluminum oxide is used for normal circuits.

Innovacera manufactures high-performance metalized substrates, photodiode sub-mounts, circuits, and spacers to customer specifications.

The micro-devices that can be made with ceramic film integrated circuits include filters, couplers, power dividers, microstrip transmission lines, high-power switch circuits, circulators, isolators, resistors, attenuators, and other custom-made devices as requested by the customer.

The typical sheet resistance of the ceramic substrate is 50 ohm/sq, with a range of 10-200 ohm/sq.

The power density of the ceramic substrate is 3 W/mm2 for 99.6% 0.254mm Al2O3, 8 W/mm2 for 99% 0.381mm AIN, and 10 W/mm2 for 99% 0.381mm BeO.

The temperature coefficient of resistance for the ceramic substrate is ±100ppm/°C.