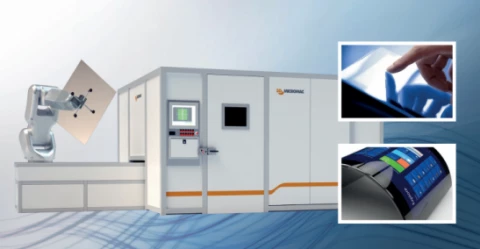

microSHAPE Highly Productive Laser Processing Workstation

Description

3D-Micromac‘s microSHAPE laser system is a modular platform designed for high accurate and high dynamic processing of large and flat substrates. The highly versatile system allows to combine different laser processes, such as laser cutting, micromachining, etc., as well as the processing with multiple working heads. The availability of several handling and inspection options enables the system to be a highly efficient production platform. microSHAPE is an industry-proven solution for all kind of ablative and non ablative cutting or structuring processes. This includes filamentation, thermal laser separation, half cut or full cut, and engraving processes. The microSHAPE is suitable for machining a variety of substrates, e.g. glass, metals, polymer, ceramics, display stacks and coated substrates.

microSHAPE Highly Productive Laser Processing Workstation

Specifications |

|

|---|---|

| Platform Type: | Gantry |

| Materials: | Steel, Iron, Alloy, Aluminum, Brass, Copper, Gold, Silver, Nickel, Titanium, Platinum, Glass, Plastic, Ceramic, Polymers |

| Laser Type: | Fiber Laser, Diode Laser |

| Max Laser Output Power: | >1000 W |

| Processing Length (X): | 2500 mm |

| Processing Length (Y): | 2250 mm |

| Max Processing Length (Z): | 10 mm |

| Max Processing Speed: | - mm/sec |

Features

Applications

Our laser processing workstations are suitable for -

Separation (modification, cleaving)

Structuring

Half cut/full cut

Peeling

Engraving/marking

Laser cutting and engraving can be done on various materials, such as -

Glass

Metal

Polymer

Ceramics

Display stacks

Coated substrates

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Germany

-

Sold by:

-

On FindLight:

External Vendor

Claim 3D Micromac Page to edit and add data

Frequently Asked Questions

The laser processing workstations are suitable for separation (modification, cleaving), structuring, half cut/full cut, peeling, engraving/marking. Laser cutting and engraving can be done on various materials, such as glass, metal, polymer, ceramics, display stacks, and coated substrates.

The platform is based on a gantry design which can easily be configured in dynamics, metrology, handling as well as laser and beam delivery components. Depending on the final configuration, an axis accuracy of ± 2 μm, a process accuracy of ±10 µm, and processing speeds of up to 1.5 m/sec are possible to realize.

The typical applications of microSHAPE laser system are OLED cutting (sheet to cell, shape cut), glass cutting (display, cover, technical, semi-finished, ultra-thin glass), and annealing.

microSHAPE laser system is a modular platform designed for high accurate and high dynamic processing of large and flat substrates.

The substrate dimensions for microSHAPE laser system range from GEN 4 (680 x 880 mm²) to GEN 8.5 (2,200 x 2,500 mm²) with a thickness of 0.03 - 10 mm.