SENSOPTIC VISION

Description

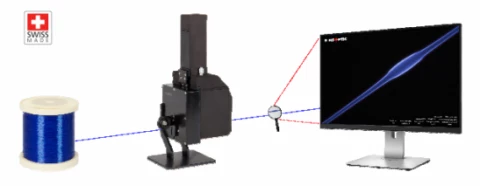

An innovative measuring system that captures instant photographs of small filament imperfections running at high line speeds, ideally suited for quality control of spools both in laboratory winding stations and in production machines. It takes advantage of advanced camera technology combined with high-speed software and real time data processing. SENSOPTIC VISION is composed of an optical PROFILE SENSOR PXL for fault detection, a VISION MODULE with an ultra fast LED flash for image recording, a SENSYSTEM NETWORK unit for electronic signal processing and a computer with SENSOFT VISION software.

SENSOPTIC VISION

Specifications |

|

|---|---|

| Wavelength: | -- nm |

| Max Optical Power: | -- mW |

Features

Diameters from 0.08 mm to 2.0 mm

Line speed up to 1000 m/min

5 Megapixel image sensor

10 μm optical image resolution

Maximum rate of 17 photos per second

Adjustable photo-trigger level

Images saved in JPG files

Easy handling and user-friendly

Filament speed measurement with encoder

Integrated precision wire guides

Net weight of 4 kg

Housing dimension: 25 x 25 x 50 cm3

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

-

Sold by:

-

On FindLight:

External Vendor

Claim SENSOPTIC SA Page to edit and add data

Frequently Asked Questions

SENSOPTIC VISION is an automatic and fast procedure, while manual inspection is an annoying and time-consuming procedure. SENSOPTIC VISION has objective control with optical sensors, while manual inspection has subjective control with naked eye. SENSOPTIC VISION can inspect full spool lengths, while manual inspection can only inspect short spool lengths. SENSOPTIC VISION can capture continuous screenshots of photos, while manual inspection can only capture static photos under the microscope. SENSOPTIC VISION has a high amount of data and statistics, while manual inspection has a low amount of data and statistics. SENSOPTIC VISION has reliable standardized statistical results, while manual inspection has uncertain and arbitrary statistical results. SENSOPTIC VISION is appropriate for fault cause analysis, while manual inspection is not so appropriate for fault cause analysis. SENSOPTIC VISION is suited for on-line process optimization, while manual inspection is not suited for on-line process optimization.

SENSOPTIC VISION has diameters from 0.08 mm to 2.0 mm, line speed up to 1000 m/min, 5 Megapixel image sensor, 10 μm optical image resolution, maximum rate of 17 photos per second, adjustable photo-trigger level, images saved in JPG files, easy handling and user-friendly, filament speed measurement with encoder, integrated precision wire guides, net weight of 4 kg, and housing dimension of 25 x 25 x 50 cm3.

SENSOPTIC VISION can capture continuous screenshots of photos, which are objective control with optical sensors, inspection of full spool lengths, high amount of data and statistics, reliable standardized statistical results, appropriate for fault cause analysis, and suited for on-line process optimization.

SENSOPTIC VISION is an innovative measuring system that captures instant photographs of small filament imperfections running at high line speeds, ideally suited for quality control of spools both in laboratory winding stations and in production machines.

SENSOPTIC VISION has a net weight of 4 kg and a housing dimension of 25 x 25 x 50 cm3.