Fiber optic collimators and their applications is the topic of this blog article.

This blog article is brought to you by Ocean Optics - a leading manufacturer of miniature spectrometers, fiber probes, and other optical components and solutions.

Fiber Optic Collimators: Introduction

Fiber optic collimators (also called fiber-optic collimators) are crucial optical components that convert the diverging output from an optical fiber into a collimated (parallel) beam, or conversely focus light from free space into a fiber. They are widely used in telecommunications, sensing, spectroscopy, research and development, laser systems, medical devices, and industrial applications.

This article explains what fiber optic collimators are, the different types available, typical applications, design parameters to watch, and guidelines for choosing the right collimator for your needs.

What is a Fiber Optic Collimator?

A fiber optic collimator generally consists of:

An optical fiber (single-mode, multimode, or polarization-maintaining)

One or more lenses (aspheric, GRIN, doublet, triplet, reflective, etc.)

A housing that ensures alignment and mounting

The basic working principle is that the fiber’s end face is placed at or near the focal point of a lens. Light exiting the fiber spreads out; if positioned correctly relative to the lens, the lens converts that diverging cone into a beam with minimal divergence (a collimated beam). The divergence and spot size depend on the fiber mode field diameter (MFD) (for single-mode or PM fiber), or the core size / NA (for multimode), the focal length of the lens, and lens quality.

Factors like lens aberrations, coatings, alignment precision, and mechanical stability greatly affect performance: wavefront quality, beam divergence, back reflections, insertion loss, etc.

Types of Fiber Optic Collimators

Here are common types and their pros & cons.

Fixed (Aspheric or Singlet/Doublet) Collimators

These are factory-aligned, non-adjustable collimators designed to produce a specific beam diameter and divergence at a design wavelength.

Typical lens types: aspheric or singlet/doublet lenses. Aspheric lenses minimize spherical aberration, but for larger beams or broadband use, doublets or achromats may be preferred.

Advantages: compact, robust, lower cost, less alignment needed.

Disadvantages: not adjustable, performance drops off if used far from design wavelength or with fiber having different mode or NA.

An example of a collimator with a single lens for UV wavelengths.

Adjustable / Focus-Tunable Collimators

These allow you to shift the fiber-to-lens distance (or lens-to-fiber) to optimize the collimation (spot size / divergence) for the wavelength or distance you care about. Example: YSenser’s adjustable aspheric collimator with FC/APC connector.

Useful when you have multiple wavelengths or want to tune alignment, or need to adapt for being farther away.

Trade-off: more expensive, potentially larger and mechanically more complex; alignment can drift.

An example of an adjustable aspheric fiber optic collimator

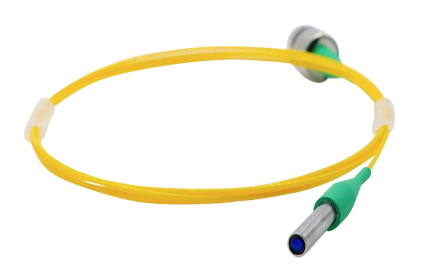

GRIN (Gradient-Index) Lens Collimators / Pigtailed Collimators

GRIN lenses use a refractive index gradient in the lens material to focus light without needing more complex curved optics. They are small, compact, and often pigtailed (fiber built in) for ease of use.

Good for compact setups, OEM systems, where space is limited.

Limitations: often smaller clear aperture; limited beam diameter; aberrations if used far off design parameters.

Reflective Collimators (Mirrors / Parabolic / Off-Axis Parabola)

Use mirrors instead of lenses; e.g. off-axis parabolic mirrors. These have the advantage that focal length does not depend on wavelength, so chromatic aberration is minimal.

Useful for broadband sources or applications where multiple wavelengths are present.

Downsides: potentially bulkier, more difficult alignment, possibly more expensive; mirror coatings require care (reflectivity, durability).

Achromatic / Triplet / Doublet Collimators

Designed to work well over a broader wavelength range (especially visible + NIR). They reduce chromatic aberration and produce better beam quality (lower wavefront error, lower M²).

Triplet lens designs or achromatic doublets are common in applications needing high beam quality.

Achromatic fiber optic collimator

Miniature / High-Power / Specialty Fiber Optic Collimators

Miniature designs (for tight space, fiber-probes, OEM modules).

High power collimators, with higher damage thresholds, special coatings, perhaps air cooling or robust housings.

Some designs also involve UHV (ultrahigh vacuum) compatibility, special materials (sapphire, fused silica) for extreme wavelength or durability.

Key Performance Parameters & Design Considerations

When selecting a fiber optic collimator, you’ll want to pay attention to:

| Parameter | Why It Matters |

|---|---|

| Wavelength / Coating | Lens coatings (anti-reflection) and material must match the operating wavelength(s). Efficiency, back-reflection, damage threshold depend on this. |

| Mode / Fiber Type | Single-mode, multimode, PM fiber have different mode field diameters or core/NA. These affect divergence and beam quality. |

| Beam Diameter & Divergence | Related to focal length and fiber’s mode field or core size. Smaller divergence means better collimation but requires longer focal length or high lens quality. |

| Optical Quality / Wavefront Error | For sensitive applications (interferometry, free-space communication, microscopy), aberrations or wavefront error degrade performance. |

| Alignment and Mechanical Stability | Adjustable designs allow fine tuning; fixed ones need precise factory alignment. Mechanical stability (drift, vibration, thermal expansion) affects consistency. |

| Clear Aperture | Determines maximum beam size and working distance. Restricted aperture can clip beam or cause losses. |

| Damage Threshold / Power Handling | For high power lasers, collimator must withstand high intensity; choice of lens material, coating, housing important. |

| Connector / Mounting Style | FC/PC, FC/APC, SMA, bare fiber, pigtailed, etc. Also how you physically mount or align the collimator in your system. |

Major Applications of Fiber Optic Collimators

Fiber optic collimators are used in many fields; here are key examples.

Telecommunications & Free-Space Optical Links

Collimate fiber outputs for free space optical links (FSO), optical interconnects, or laser communication.

Coupling between fibers over free space (fiber-collimator pairs) in optical labs or bench setups.

Spectroscopy & Sensing

Collimating light from fibers to illuminate samples or collecting light into fiber from samples.

In fiber-sensor systems, for example gas sensing, Raman, fluorescence, or environmental sensors.

Laser Systems & Material Processing

Collimators help shape the beam exiting fiber for laser cutting, micromachining, or marking.

Also used in combining or splitting beam paths or in feedback systems.

Biomedical & Medical Devices

Laser therapy, photodynamic therapy, optical coherence tomography (OCT), microscopy. Need for precise beam shape, low back-reflectance, and perhaps sterilizable or biocompatible materials.

Research & Academic Labs

Experiments in nonlinear optics, interferometry, free-space coupling, quantum optics. Here beam quality, stability, and minimal aberrations are often more critical.

How to Choose the Right Fiber Optic Collimators

Putting together the above, here is a decision framework:

Define your operating wavelength(s) — single wavelength or broadband? Is visible, NIR, UV, IR?

Decide fiber type — single-mode, multimode, or PM. The mode field diameter / core size & NA determine divergence.

Select required beam diameter & divergence — how large a collimated beam do you need, how much divergence is acceptable?

Choose lens type —

If cost and size are constraints, fixed aspheric might suffice.

If you need flexibility or multiple wavelengths, adjustable, achromatic/triplet, or reflective might be better.

Consider optical quality & stability — wavefront error, beam uniformity, alignment stability, mechanical housing, thermal properties.

Power and environmental demands — high-power lasers, harsh environments, UHV compatibility, vacuum, temperature range.

Connector / Mount compatibility — is the system connectorized (SMA, FC, bare-fiber), pigtailed, how to mount, etc.

Budget vs Performance Trade-offs — high precision optics cost more; sometimes a mid-range fixed collimator is enough for many industrial or lab uses.

Common Mistakes & Pitfalls

Using a fixed collimator far from its design wavelength → large divergence, more losses.

Neglecting back reflections into the fiber, which can interfere with measurement or damage lasers. Choosing APC vs PC vs bare fiber matters.

Underestimating alignment tolerance: misalignment causes beam clipping, increased divergence, or beam pointing instability.

Ignoring environmental factors: thermal drift, vibration, humidity can degrade performance.

Summary & Best Practices

Fiber optic collimators are foundational in fiber optics systems wherever you need to get light out of a fiber into free space, or vice versa, with low loss, stable performance, and precise beam shape. The right collimator depends on your wavelength, fiber type, beam size, required divergence, power, and mechanical / environmental constraints.

Best practices:

Choose the collimator type (fixed / adjustable / GRIN / reflective) that aligns with your flexibility vs precision trade-off.

Pay attention to lens coatings, alignment, and housing stability.

Ensure mechanical mounting supports alignment and does not allow drift.

Test with the actual fiber and wavelength you plan to use (and environmental conditions) rather than just relying on datasheet specs.

References & Further Reading

Hecht, E. Optics, 5th Edition. Pearson, 2016 – Chapter on Gaussian beams and lens systems.

Saleh, B.E.A., and Teich, M.C. Fundamentals of Photonics, 3rd Edition. Wiley, 2019 – Sections on fiber optics and free-space coupling.

Newport Corporation. Technical Note: Choosing the Right Fiber Collimator.

Thorlabs Inc. Fiber Collimator Selection Guide.

Agiltron Inc. Fiber Optical Collimators: Specifications and Applications.

Meisu Optics. Working Principle and Applications of Optical Fiber Collimator.

Accu-Glass Products. UHV Fiber Collimators for Extreme Environments.

Tsai, C.C., and Ho, P.T. “Coupling Efficiency of Single-Mode Optical Fiber and Collimator Systems.” Applied Optics, Vol. 22, No. 3, 1983.

Bach, H. and Neuroth, N. The Properties of Optical Glass. Springer, 1998 – Details on lens material choice and optical properties.