Optical coatings for high-power lasers is the topic that we will explore in this blog article. We will look at the types of optical coatings for high-power lasers, their performance characteristics, durability factors, and practical applications across industries.

This blog article is brought to you FindLight with the support of RPMC Lasers Inc. - a leader in the world of lasers and laser technologies.

Courtesy of UM Optics

Optical Coatings for High-Power Lasers: Introduction

High-power laser systems are the backbone of modern scientific research, industrial manufacturing, medical devices, and defense technologies. Ensuring that these lasers operate efficiently and reliably requires more than just high-quality laser diodes or fiber lasers. One of the most critical factors affecting performance is optical coatings.

Optical coatings determine reflectivity, transmission, and durability of laser components such as mirrors, lenses, beam splitters, and windows. Choosing the correct coating can significantly influence the laser’s efficiency, lifespan, and safety.

Understanding Optical Coatings

Optical coatings are thin-film layers deposited on optical surfaces to modify the reflection, transmission, and absorption of light. These coatings are engineered at the nanometer scale and are crucial for controlling how laser light interacts with optical components.

Key functions of optical coatings in high-power lasers include:

Increasing transmission through lenses and windows (Anti-Reflective coatings, AR)

Maximizing reflection on mirrors (High-Reflective coatings, HR)

Protecting components from laser-induced damage

Managing wavelength-specific performance

Selecting the right coating ensures the laser system maintains high efficiency, stability, and long operational life.

Types of Optical Coatings

Different coatings serve different purposes depending on the laser system and application.

Anti-Reflective (AR) Coatings

AR coatings minimize reflections from optical surfaces. They are essential for lenses, windows, and protective covers in laser systems. By reducing reflection losses, AR coatings enhance power throughput and reduce stray light that can cause system inefficiencies.

Applications: Laser machining, medical lasers, high-precision research optics.

High-Reflective (HR) Coatings

HR coatings maximize reflection on mirrors and reflective surfaces. These coatings are critical in laser resonators, beam steering mirrors, and optical cavities.

Applications: Solid-state lasers, fiber lasers, laser resonators, and interferometers.

Dielectric Coatings

Dielectric coatings consist of alternating layers of high and low refractive index materials. They offer precise control over reflection and transmission and are highly resistant to laser-induced damage.

Applications: High-power pulsed lasers, wavelength-selective mirrors, and multi-layer mirrors.

Metallic Coatings

Metallic coatings, such as gold or aluminum, provide broadband reflection across a wide wavelength range. While their reflectivity is generally lower than dielectric coatings, they are robust and often used in broadband systems.

Applications: Infrared lasers, industrial laser systems, optical alignment tools.

Performance Considerations for High-Power Lasers

When selecting coatings for high-power lasers, several performance parameters must be considered:

Reflectivity and Transmission

The coating should provide optimal reflectivity or transmission for the laser wavelength. Even minor losses can lead to significant power reductions in high-power systems.

Absorption and Thermal Management

High-power lasers generate significant heat. Coatings must have low absorption to prevent thermal lensing, surface deformation, or damage. Advanced dielectric coatings often provide high laser damage thresholds (LDT).

Wavelength Specificity

Coatings must be designed for the laser’s operating wavelength. Broadband coatings work across multiple wavelengths, while narrowband coatings are tuned for specific lasers, such as 1064 nm or 532 nm systems.

Laser Damage Threshold (LDT)

The LDT indicates the maximum power density a coating can handle before sustaining damage. High-power laser systems require coatings with high LDT values, often achieved with multilayer dielectric coatings.

Durability and Environmental Factors

Optical coatings must withstand mechanical, thermal, and environmental stress. Key factors include:

Humidity and Corrosion Resistance: Protective coatings prevent degradation in humid or corrosive environments.

Mechanical Hardness: Hard coatings resist scratches during handling and cleaning.

Thermal Cycling: Coatings must maintain performance under rapid temperature changes typical in high-power laser applications.

Choosing coatings that account for environmental and operational stresses ensures long-term stability and reliability.

Practical Applications Across Industries

High-power lasers are used in many sectors, and the right optical coatings can dramatically improve performance and longevity.

Industrial Manufacturing

Laser cutting, welding, and engraving require AR coatings on lenses to maximize transmitted power and HR coatings on mirrors for resonator efficiency.

Medical and Research Applications

Precision surgical lasers and diagnostic systems rely on coatings for high throughput, minimal losses, and sterilization durability.

Aerospace and Defense

Lidar systems, targeting lasers, and optical navigation devices use dielectric HR coatings for high reflectivity and laser resistance under extreme conditions.

Scientific Research

Optical experiments, spectroscopy, and high-energy physics setups depend on coatings with tight wavelength control and high LDT to maintain accuracy.

Tips for Selecting Optical Coatings

When choosing coatings for high-power lasers, it is essential to ensure that the coating is optimized for the laser’s operating wavelength. Different types of lasers, such as continuous-wave (CW) and pulsed systems, have varying requirements for thermal management and laser damage threshold (LDT), so these factors should be carefully considered. Environmental conditions, including humidity, temperature fluctuations, and mechanical handling, can also affect the performance and longevity of optical coatings. It is important to review manufacturer specifications to confirm key parameters such as LDT, reflectivity, and transmission performance.

Finally, when selecting coatings, a balance should be struck between cost and performance, as advanced dielectric coatings may have a higher upfront cost but typically offer greater durability and higher LDT, ensuring long-term reliability.

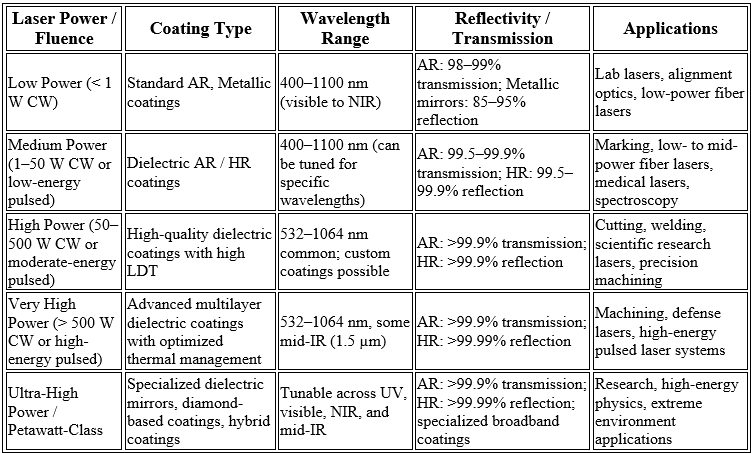

Table 1. Summary of coating types for various laser power levels and spectral ranges

Notes: LDT = Laser Damage Threshold; always choose coatings rated above your system’s expected power density; CW = Continuous Wave; pulsed lasers require coatings that withstand high peak powers; Wavelength selection must match the laser source; broadband coatings are available but may have slightly lower LDT; Environmental factors (temperature, humidity, contamination) can affect coating performance and should be considered.

Emerging Trends and Innovations

Recent innovations in optical coatings for high-power lasers include:

Hybrid Dielectric-Metallic Coatings: Combining broadband reflection with high LDT.

Nano-Structured Coatings: Reducing surface absorption and increasing damage thresholds.

Customized Multilayer Designs: Tailored coatings for ultra-short pulsed lasers, fiber lasers, and high-energy laser systems.

These advancements are improving laser efficiency, extending operational life, and enabling new applications in industrial, medical, and defense fields.

Conclusion

Choosing the right optical coatings for high-power lasers is critical for system efficiency, durability, and precision. Understanding the types of coatings, performance factors, environmental considerations, and applications ensures optimal performance across industries.

Whether you are designing industrial laser systems, medical equipment, or scientific instruments, investing in high-quality optical coatings will maximize laser efficiency, reduce downtime, and extend the lifetime of optical components.

By staying informed on the latest coating technologies and trends, engineers and researchers can make strategic choices that enhance laser performance in demanding applications.

References

J. R. Lawrence et al. – Development of High-Power Laser Coatings

Discusses methods to reduce electric field intensity in multilayer reflectors under high-power laser irradiation to improve damage thresholds.M. Richardson – Coatings for Petawatt-Class High-Energy Lasers

Overview of optical coatings in high-energy laser systems, focusing on high transparency and laser-induced damage thresholds.S. Zhao, L. Chen – Ultra-Low Stress and High Laser Damage Threshold Optical Coatings

Analyzes stress states in films and introduces multilayer coating design strategies to enhance laser damage resistance.R. L. Snyder et al. – Laser Damage Thresholds of Optical Coatings

Reviews laser-induced damage mechanisms and future developments in high-power optical coatings.Laser Components Team – New Coating Techniques for Optics in High-Power Laser Systems

Provides insights into coating techniques that enhance reflectivity, laser damage thresholds, and thermal stability.R. D. Schroll et al. – Diamond Mirrors for High-Power Lasers

Research on fabricating highly reflective dielectric mirrors that withstand high laser power without damage.J. E. Neira, M. T. Hutchinson – Future Trends in Optical Coatings for High-Power Laser Applications

Discusses future trends including sol-gel AR coatings and e-beam-deposited HR coatings.