Laser energy vs. power meters and their differences is the topic of this blog post.

This article is brought to you by Gentec-EO, a leading developer and manufacturer of laser beam measurement solutions.

Laser Energy Meters vs. Power Meters: Understanding the Difference

Laser systems are now central to manufacturing, research, medicine, and defense, but accurately measuring their performance remains crucial. Two of the most common diagnostic tools are laser energy meters and laser power meters, and while their names are sometimes used interchangeably, they are designed to measure fundamentally different things.

In this blog article, we’ll explore what each device does, how energy measurement differs from power measurement, and how to choose the right instrument for your laser type and application.

Understanding Laser Energy and Laser Power

Before diving into instrumentation, it’s important to clarify the difference between laser energy and laser power.

Laser energy refers to the total amount of energy delivered by a pulse or a series of pulses. It is typically expressed in joules (J) or millijoules (mJ).

Laser power, by contrast, is the rate at which energy is delivered over time, measured in watts (W) or milliwatts (mW). For continuous-wave (CW) lasers, power is the most relevant metric. For pulsed lasers, energy per pulse is often more critical, especially in applications like materials processing, where peak energy density drives ablation or modification.

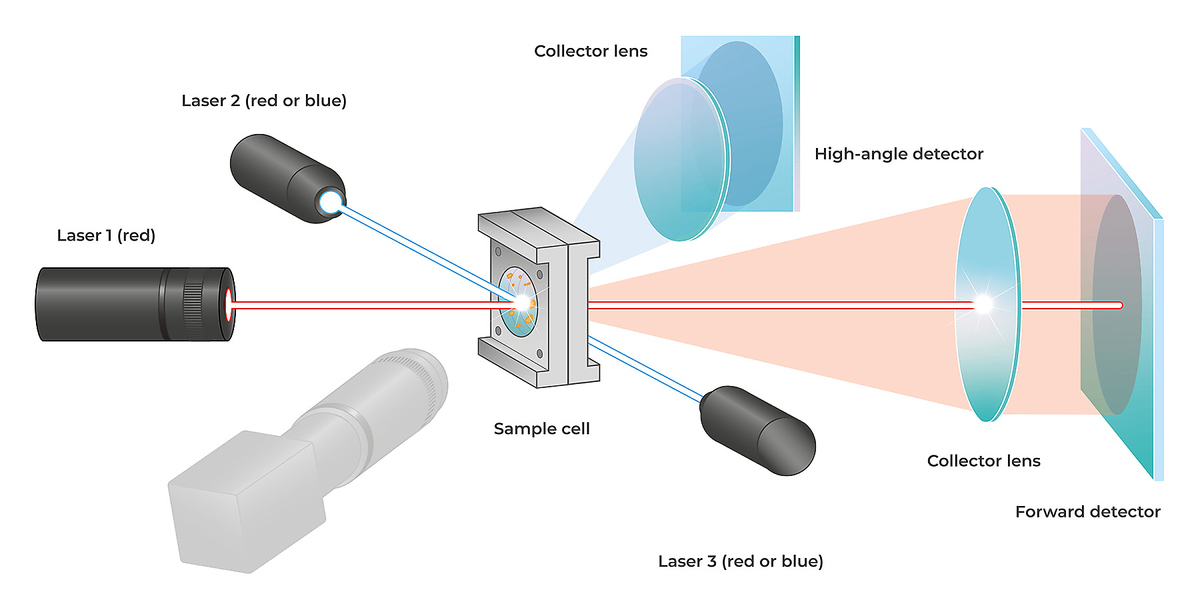

Laser energy and power detectors are used in many applications across various industries and are often key enabling elements in complex measurements systems.

Schematic representation of a complex light scattering and measurement system utilizing multiple laser light energy or power detectors (courtesy of Microtrac)

What Is a Laser Energy Meter?

A laser energy meter is designed to measure the energy contained in individual laser pulses. These devices typically work with pulsed lasers, including nanosecond, picosecond, and femtosecond systems, as well as Q-switched or mode-locked sources.

They use specialized sensors such as pyroelectric detectors, which respond to the heat generated by a laser pulse and translate it into a measurable voltage signal. Modern energy meters often feature fast response times, allowing them to measure pulse-to-pulse energy stability and fluctuations.

Energy meters are indispensable in applications where total energy per shot determines performance – for example, in laser surgery, LIDAR systems, micromachining, and scientific experiments requiring precise fluence control.

What Is a Laser Power Meter?

A laser power meter measures the average optical power of a laser over a given time period. These instruments are most commonly used with continuous-wave lasers, but can also measure the average power of pulsed sources.

Power meters generally employ thermopile sensors, photodiodes, or integrating spheres to measure the steady-state power level. The output is given in watts, enabling users to verify that a laser is producing the intended output or remains within safe operating limits.

In industrial settings, such as laser cutting, welding, or semiconductor manufacturing, power meters help maintain process consistency and prevent damage to optical components caused by power drifts.

Key Differences Between Energy and Power Measurement

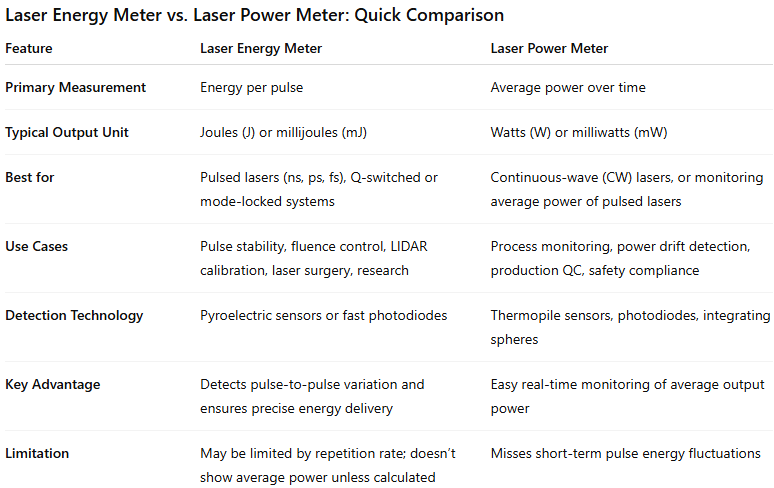

Although both devices are used to characterize laser output, they answer different questions:

Energy meters tell you “how much energy was in that pulse?”

Power meters tell you “how much energy per second is the laser delivering?”

For pulsed lasers, power can be derived from energy if the pulse repetition rate is known (Power = Energy × Repetition Rate). However, this derived value hides pulse-to-pulse variation. Conversely, power meters may miss short-term fluctuations that an energy meter can detect.

In practical terms, this means that energy meters are preferred for diagnosing pulse stability, while power meters are better suited for long-term monitoring of average output.

Choosing Between Laser Energy and Power Meters

The choice between a laser energy meter and a power meter largely depends on your laser source and measurement goal.

For continuous-wave lasers such as DPSS CW lasers, fiber lasers, and diode lasers, a power meter is generally sufficient.

For pulsed lasers, especially those used in precision materials processing, medical procedures, or research experiments, an energy meter is essential to monitor pulse energy consistency.

In some setups, both devices are used in combination — power meters to monitor average performance and energy meters to capture pulse-to-pulse variations.

Measurement Challenges and Best Practices

Accurate laser measurement is not trivial. Detector selection, sensor aperture size, and wavelength calibration all affect results. Energy meters may suffer from limited repetition rate capability, while power meters can saturate under high peak powers if used improperly with pulsed lasers.

Best practice involves choosing sensors matched to your wavelength, power range, and beam size, regularly calibrating instruments, and avoiding measurement conditions that risk sensor damage. Some systems now integrate energy and power measurement in a single unit, providing a more complete picture of laser performance.

Applications Across Industries

The correct use of laser energy and power meters is vital across many fields:

Industrial Laser Processing: Ensuring consistent ablation thresholds for micromachining or cutting.

Medical Lasers: Safely delivering the correct energy per pulse during cosmetology or dental surgery or dermatology treatments.

Scientific Research: Measuring pulse-to-pulse stability in ultrafast laser experiments.

Defense and Aerospace: Verifying output of range-finding and target-designation lasers.

Each application has unique tolerances and regulatory standards that dictate which measurement parameter (energy or power) must be controlled most tightly.

Future Trends in Laser Measurement

Advancements in photonics are driving new requirements for metrology. Integrated power and energy meters are becoming more common, capable of handling high-repetition ultrafast lasers while providing real-time data logging.

In addition, software integration with manufacturing execution systems (MES) and AI-driven predictive maintenance tools are enabling closed-loop process control based on live energy/power readings. This trend is particularly important in additive manufacturing and semiconductor lithography, where even small power drifts can lead to yield loss.

Conclusion

Laser energy meters and power meters are complementary tools that together provide a full understanding of a laser system’s behavior. Energy meters excel at characterizing individual pulses and ensuring pulse-to-pulse consistency, while power meters are ideal for monitoring average output over time.

Whether you are an engineer maintaining a production line, a researcher fine-tuning an ultrafast experiment, or a medical device integrator, knowing when to use each measurement technique will help ensure safety, performance, and efficiency.

References & Further Reading

Gentec-EO Knowledge Center – Laser Power and Energy Measurement Basics

https://www.gentec-eo.com/learning-centerOphir Photonics – Choosing the Right Power and Energy Meter

https://www.ophiropt.com/laser–measurement/knowledge-centerJ. E. Moloney & P. J. Wragg, “Laser Diagnostics and Measurements”, Springer Handbook of Lasers and Optics, Springer, 2021.

ISO 11554:2017 – “Test methods for laser power (energy) meters.” International Organization for Standardization.

Diels, J.-C., & Rudolph, W. “Ultrashort Laser Pulse Phenomena.” Academic Press, 2019.

J. M. Liu, “Principles of Photonics.” Cambridge University Press, 2016. (Chapter on Laser Power and Energy Measurement)

National Institute of Standards and Technology (NIST) – Calibration of Laser Power and Energy Meters

https://www.nist.gov/pml