In 1842, Johann Doppler delivered his paper on Doppler effect to Royal Bohemian Society. In his paper “On the Colored Light of Double Stars and Some Other Heavenly Bodies”, he arrived at the form of light emission by moving bodies. Years later the effect was coined by his name and used to detect the motion of far away bodies in the universe. It is interesting to note that, similar to detecting movement in far away macroscopic bodies, this method can also be used to detect in microscopic bodies. This method, which is often used to measure liquid flows in capillary channels is called Laser Doppler Flowmetry.

Doppler Flowmetry has wide applications in medicine in terms of measuring blood flow in blood vessels. In particular, blood flow in the eye, heart, kidney, bone, muscle and skin have successfully been measured with the Doppler method. Depending on the characteristics of the measured region, the output signal is processed differently, although the general setup can be quite similar.

In this blog post we will discuss the method and the setup of Laser Doppler Flowmetry, with its applications in imaging blood flow in retina, heart and skin.

Doppler Effect

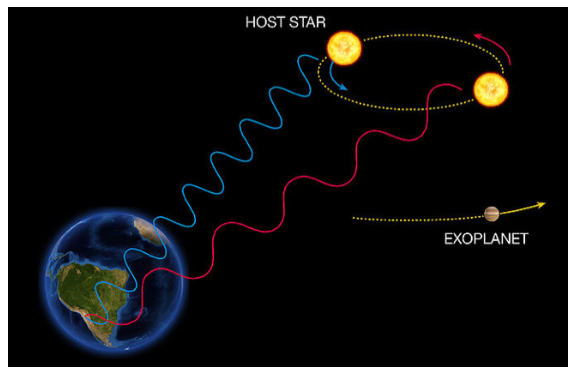

Doppler effect is the observation that moving objects emit light at a different frequency than stationary objects. Specifically, if an object is moving away from you, the emitted light is of lower frequency. The emitted light is at a higher frequency if the object is moving towards you. This shift in the frequency can be used to observe the movement of distant stars as shown in the image below. The star emits a blue-shifted light if it is moving towards the earth, and red shifted otherwise.

Doppler effect showing the red-shit and blue-shift of a moving star.

The shifted spectra is compared with the known emission profile of starts to measure the shift.

Laser Doppler Flowmetry Setup

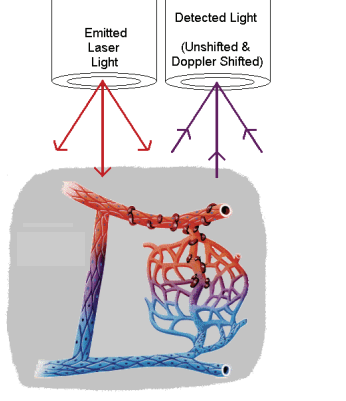

Laser Doppler Flowmetry (LDF) uses the Doppler effect to measure the speed of red blood cells. Here the incident light in the red wavelength is incident upon the blood vessels. The red blood cells absorb the incident light and reflect light with a shifted frequency depending on the flow velocity. Optical fibers can be used for this purpose to control the delivery of light. Two fibers are typically used with the detected light collected in a different fiber. The image below shows the schematic of collecting light in Laser Doppler Flowmetry.

Excitation and detection of blood vessels with laser light for flowmetry. Courtesy biopac.

The light wavelength can be changed within a narrow window to control the depth of penetration depending on the regions of the body. For example, different wavelengths penetrate at different depths in skin. Optimal wavelength choice is required if one wants to image surface or deep tissue blood flow.

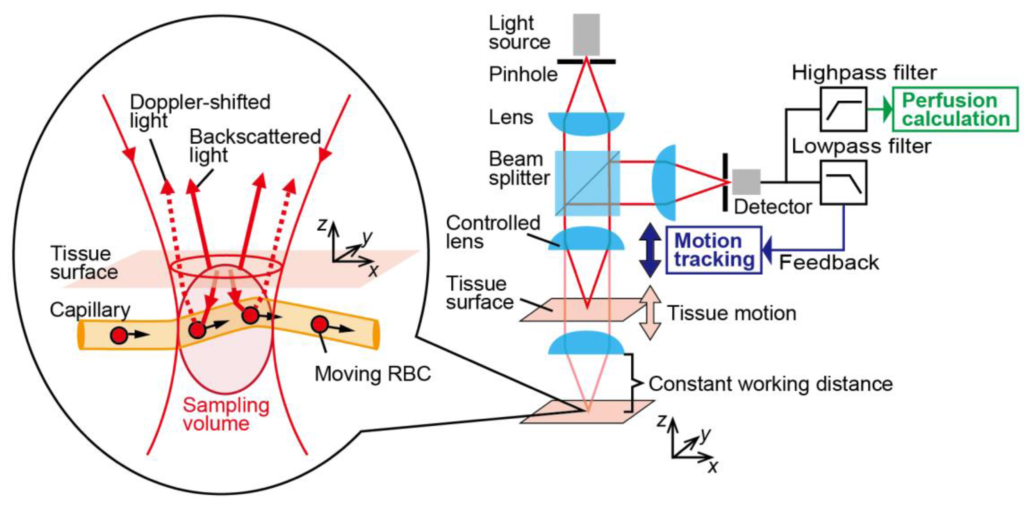

Doppler flowmetry has some additional electronics to process the detected spectrum to identify the velocity profile. Imaging can also be done with less fiber optics if the sample is mounted on a surface. The image below shows a lens setup to focus light into detectors with some additional electronics for flow calculation.

Doppler Flowmetry setup with accompanying optical system and electronics. Courtesy mdpi.

The detected light is cross correlated with the input signal to obtain a power spectrum. The wider this profile, the wider the velocity distribution in the vessel.

Applications of Laser Doppler Flowmetry

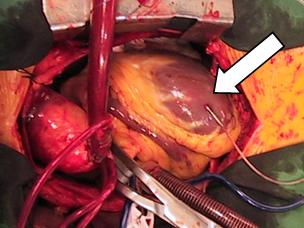

1. Cardiac Blood Flow

During cardiac surgery, it is necessary to make sure there is a constant blood flow to the heart. Since the measurement is direct here, a fiber optic cable can be held close to the blood vessel to detect the reflected light. This has been used in invasive transmyocardial surgery to measure the perfusion of blood while making small incisions in the heart. The image below shows laser Doppler flow measurements during a cardiac surgery.

Flowmetry during cardiac surgery. The arrow indicated the fiber used for Doppler flowmetry.

2. Retinal Blood Flow

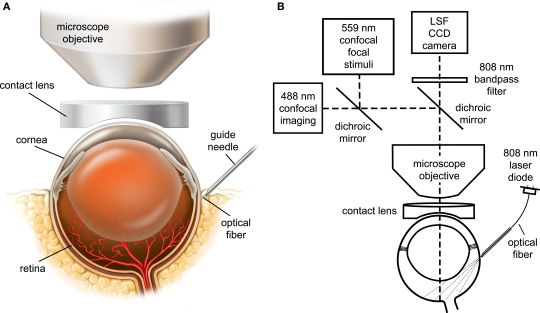

Retinal blood flow can still be imaged with visible light as the eye is transparent to the visible region. The objective is to measure retinal blood flow. Optical fibers are not necessary here, instead a lens setup is employed as shown below.

Flowmetry setup for imaging retinal blood flow. Courtesy ResearchGate

This is used in diabetic retinopathy surgery where the retinal blood vessels suffer from leaking blood into the surrounding areas. The surgery involves clotting the ends of blood vessels to stop the bleeding. Doppler flowmetry technique can be used to check the flow in the back of the eye to make sure the clotting process has occurred properly. Apart from being useful in heart and eye surgery to monitor blood flow, it can also be used to monitor blood flow in bone, kidney, and brain surgeries similar to the methods above.

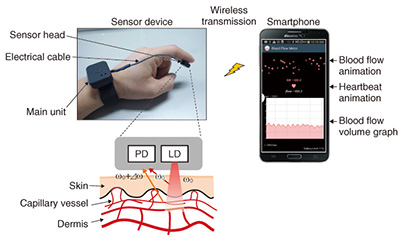

3. Skin Blood Flow

Skin flowmetry is different in imaging characteristics as the blood vessels are not directly exposed for measurement. While this contributes to some noise in the measurements, choosing the right wavelength can solve this problem. Moreover, it can be used to vary measurements for surface and deep tissue blood flow. Handheld measurements method using a smartphone with integrated laser diodes have been proposed to image blood flow in hand as in the below setup.

Handheld setup for surface blood flow measurement. Courtesy ntt-review

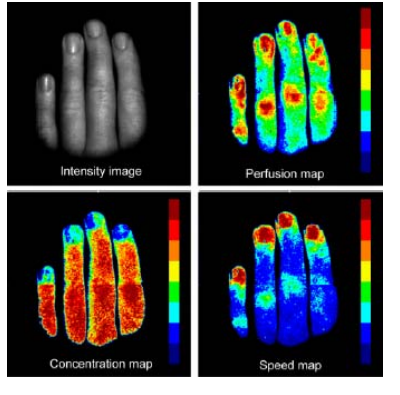

Additional measurements from the same setup can also be made from the reflected signal using digital electronic processing techniques. From the intensity, the concentration of the blood in different regions can be detected. The various quantities imaged is shown below for a hand.

Concentration and flow maps generated from flowmetry. Courtesy Ferreira

Hand held measurements of Laser Doppler Flowmetry with a smartphone gives a portable diagnostic system for detecting abnormal flow from pressure variations.

Check out FindLight’s collection of devices for laser diodes, fiber optics, and imaging systems that can be used in Doppler Flowmetry.

I had a technical question about how the BLOOD FLOW METER works, can you help me?

What questions do you have about the flow meter?

Hello

Thank you very much for giving us your time

We are a group working on making this device, we encountered a problem during the work process.

We used a red rotating plate for the blood simulator and a thin translucent plate for the skin simulator.

We shined the laser light obliquely on the semi-transparent plate, part of the light was reflected and part passed, hit the rotating plate and was reflected from it; We changed the optical instrument so that both reflections fall at the same point and placed the detector at that point. The detector is connected to an amplification circuit, which according to our calculations at a frequency of 70kHz, the gain is 2500, and the output of the amplification circuit is connected to the oscilloscope.

In the oscilloscope, no other signal was displayed except the noise signal, which was still there even after the laser was cut off. But when we hit the LED light on the detector, the signal was observed. What is the problem with our work that the LED light gives a signal, the interference of the laser reflection does not?!

Based on your description, there are several possibilities that could lead to this issue. Let’s break them down one by one:

1. Laser Intensity and Detection Sensitivity: It’s possible that the intensity of the laser light being reflected off both the skin simulator and the rotating plate is too low to be detected above the noise floor of your detector and amplification setup. The LED might be giving off a higher or more direct intensity on the detector.

2. Wavelength Sensitivity: Detectors have specific sensitivity curves, meaning they’re more sensitive to certain wavelengths (colors) of light. If your laser has a wavelength outside of the detector’s most sensitive range, and the LED falls within that range, then the detector will more readily pick up the LED light.

3. Interference & Coherence: Lasers are coherent light sources, meaning their waves are in phase. When you’re trying to capture interference, it’s crucial to ensure that the phase difference between the light reflecting off the two plates is consistent. If the phase difference is shifting too rapidly (because of, say, slight wobbles in the rotating plate), you might not see a consistent interference pattern.

4. Amplification Circuit Frequency: Your amplification circuit is designed for a gain of 2500 at 70kHz. If the signal you’re trying to detect from the laser is not near this frequency, it might be getting attenuated or not amplified enough.

5. Ambient Light & Noise: Ambient light can introduce noise. If your setup isn’t shielded from other light sources, the detector might be picking up additional light, masking the signal you’re looking for. Ensure you’re working in controlled lighting conditions.

6. Polarization: Lasers often produce polarized light. If there’s any element in your setup that affects the polarization (like certain types of plates or reflections), this could interfere with the detection.

7. Alignment: Make sure the alignment of your optical setup is precise. Any slight misalignment could mean that the light doesn’t reflect as intended or doesn’t hit the detector correctly.

What to try next:

1. Test Laser Output: Ensure that the laser is producing the intended output and is not malfunctioning.

2. Adjust Laser Intensity: If possible, try increasing the intensity or focusing the laser beam to get a stronger reflection.

3. Frequency Analysis: If you have the capability, perform a frequency analysis on the output to see if there’s any signal around 70kHz (or elsewhere) that might be getting drowned out by noise or not being amplified correctly.

4. Re-check Setup: Go through your optical setup again, ensuring all elements are correctly aligned and at the intended angles.

5. Shielding: Add shields to block out external light sources.

6. Check for Coherence: Ensure that the laser’s interference pattern is stable. You could test this by removing the rotating plate and just reflecting the laser off the skin simulator to see if the interference pattern appears.

Troubleshooting often requires a systematic approach, eliminating one potential issue at a time until you find the root cause.