Blue diode lasers in industrial manufacturing is the topic of this blog article.

This article is brought to you by LECC Technology Co., Ltd. – a leading manufacturer of laser diode solutions

Introduction – A New Era for Industrial Laser Processing

For decades, infrared (IR) lasers have dominated industrial manufacturing. Fiber lasers, CO₂ lasers, and solid-state Nd:YAG systems have powered everything from sheet-metal cutting to micro-welding and additive manufacturing. But as industries increasingly rely on highly conductive and reflective metals, especially copper and aluminum, the limitations of IR processing have become more apparent. Excessive reflectivity, unstable melt pools, high defect rates, and poor penetration in certain metals have pushed engineers to look for alternatives.

Enter blue diode lasers, operating in the 445–460 nm wavelength range. In just a few years, blue lasers have gone from niche tools to one of the most promising solutions for next-generation manufacturing. Their unique optical properties, driven by the physics of how metals absorb light, have reshaped what is possible in welding, additive manufacturing, microfabrication, and electronic assembly. As electric vehicles, renewable energy systems, and advanced electronics continue to grow, blue diode lasers are rapidly emerging as one of the most disruptive photonics technologies of the decade.

This article explores why blue diode lasers are gaining traction, the science behind their performance, how they compare to traditional IR lasers, and what applications are driving mass adoption across global industries.

The Science Behind Blue Laser Advantage – Why Wavelength Matters

The primary reason blue diode lasers outperform infrared lasers in specific industrial tasks is rooted in absorption physics. When a metal absorbs laser light efficiently, it converts optical energy into heat more predictably and more efficiently. For many reflective metals, especially copper and gold, absorption is strongly wavelength-dependent.

Copper, for instance, absorbs:

~5% of infrared (1064 nm) laser light

~40–60% of blue (450 nm) laser light

This is an extraordinary improvement, roughly 8 to 12 times greater absorption depending on the exact alloy, surface finish, and temperature. Higher absorption means the metal melts faster, more uniformly, and with far less energy wasted. As a result, welding with a blue diode laser yields:

Higher process stability

Nearly spatter-free welds

Less porosity

Lower thermal stress

Faster process speeds

Deeper, cleaner penetration

Additionally, blue diode lasers produce a more stable and predictable melt pool because the absorption does not fluctuate as wildly as it does in infrared wavelengths, where reflectance is high and unstable at early stages of melting.

This stability is critical for industrial environments such as electric vehicle (EV) battery cell production, where defect rates must be extremely low and weld integrity is mission-critical.

Advantages of Blue Diode Lasers in Manufacturing

Superior Performance on Reflective Metals

Materials such as copper, aluminum, gold, and brass, common in electrical systems, reflect infrared laser light intensely. This leads to erratic welding behavior, keyhole instability, and high spatter. Blue lasers eliminate this challenge by coupling energy directly into the material.

Minimal Spatter and Low Heat Input

Because blue light is absorbed more efficiently, less total power is required to form a stable melt pool. This significantly reduces spatter, which is essential in industries where particulate contamination is unacceptable (e.g., battery manufacturing and microelectronics).

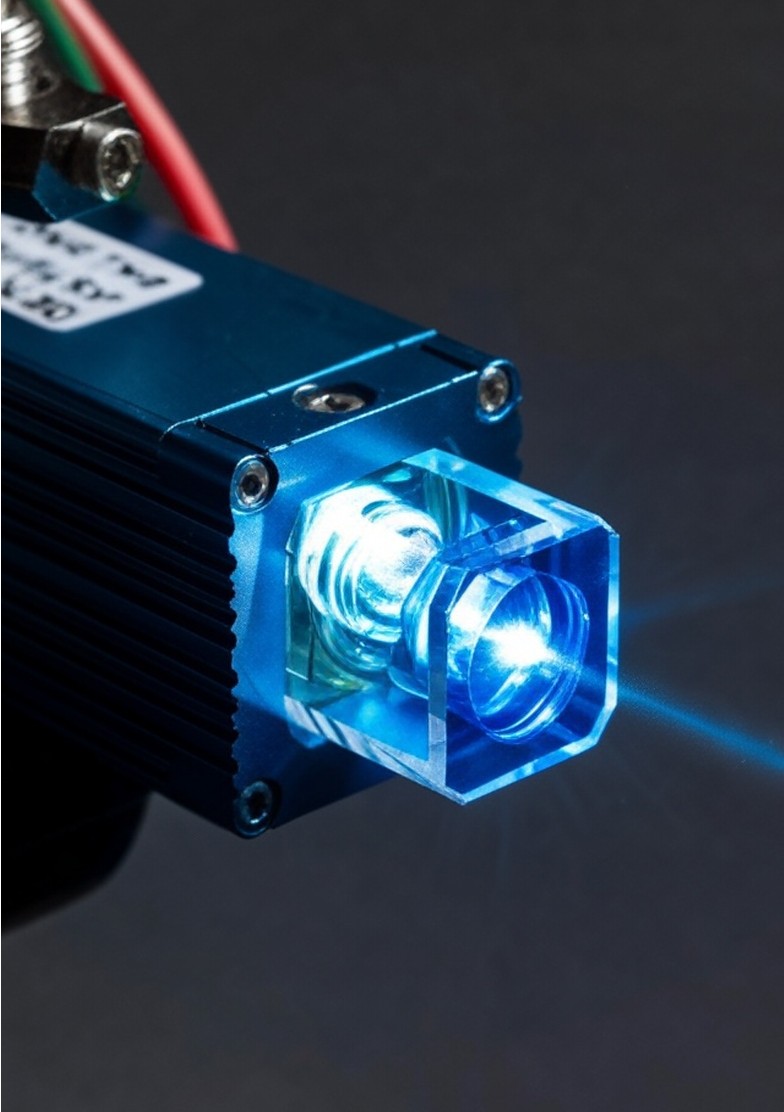

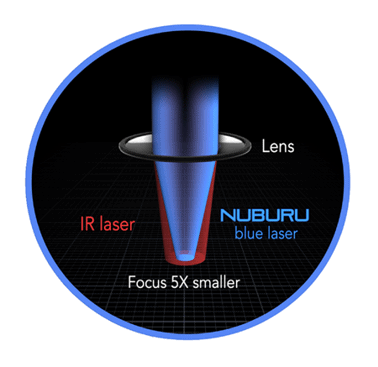

Higher Precision for Micro-Welding

Blue diode lasers offer exceptional spatial resolution because their shorter wavelength enables tighter focusing and smaller spot diameters compared to infrared systems. This gives manufacturers superior control over heat input, allowing them to perform delicate welds without damaging adjacent materials or sensitive electronic components. The enhanced absorption of blue light in conductive metals further improves stability at micro-scales, resulting in cleaner weld seams, reduced thermal distortion, and minimal rework.

Image courtesy of Aerospace Manufacturing and Design

These advantages make blue diode lasers an ideal tool for a wide range of precision micro-fabrication tasks, including:

Solder-free micro-interconnects for compact electronics and wearables

High-yield sensor assembly, where low heat is critical for preserving calibration integrity

Micro-battery welds for medical implants, IoT devices, and miniaturized power modules

Fine-feature electronics repair, enabling selective energy delivery without collateral heating

Medical device welding, where biocompatibility, cleanliness, and ultralow spatter are essential

Compact, Energy-Efficient, Solid-State Design

Blue diode lasers are inherently compact compared to traditional IR systems. They consume less power, have high electrical-to-optical efficiency, and integrate easily into robotic heads, galvo scan systems, or CNC workstations.

Scalable Power Options Using Diode Bars

Recent breakthroughs allow blue diode lasers to scale to multi-kW levels using diode bar stacks and fiber-coupled modules. This makes them viable not only for micro applications but also for heavy industrial workflows.

Image courtesy of RAYLASE

Applications Driving the Global Shift Toward Blue Laser Technology

EV Battery Manufacturing – Hairpins, Busbars, and Tabs

The electrification of transportation is arguably the biggest single driver of blue diode laser adoption. EV batteries contain large amounts of copper interconnections for current distribution. Traditional IR lasers struggle with spatter contamination, unstable weld formation, excessive reflectivity, high scrap rates.

Blue diode lasers produce consistent, deep, low-defect welds, improving both performance and throughput. They are used for:

Hairpin welding

Busbar welding

Foil tab welding

Current collector welding

Connector joining

Aluminum-to-copper dissimilar joints

The ability to reduce heat input also comes with a major benefit: there is less thermal damage to sensitive insulating materials and battery cell structures.

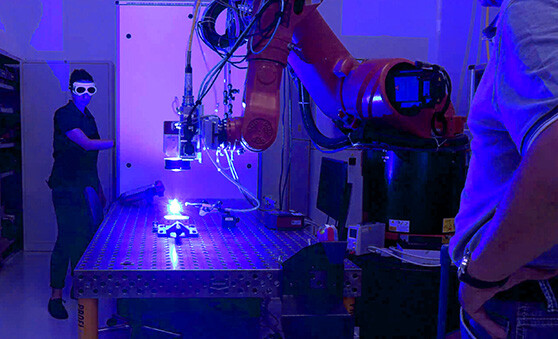

Additive Manufacturing of Conductive Metals

Powder bed fusion of copper and aluminum is notoriously difficult with IR lasers. Poor absorption leads to incomplete melting, balling, surface defects, low-density parts. Blue diode lasers, in contrast, dramatically improve powder absorption, allowing manufacturers to produce:

High-conductivity copper induction coils

Heat exchangers

RF components

Motor components

Premium aerospace connectors

This has opened new frontiers in 3D printing of high-performance conductive parts. Additionally, blue diode lasers are well-suited for:

Fine-pitch interconnect welding

Solder replacement

PCB component repair

Flexible electronics welding

Termination welding

Connector joining

Because of their small spot size and low heat load, they outperform many traditional soldering and reflow techniques. This is important in next-gen consumer electronics, wearables, and compact medical devices.

Renewable Energy and Power Electronics

In power inverters, solar charge controllers, and high-efficiency power modules, copper is the dominant conductor. Blue diode lasers allow manufacturers to create stronger, cleaner conductive joints with less risk of thermal damage to surrounding semiconductors or insulation layers.

Blue Lasers vs. Infrared Lasers – Side-by-Side Comparison

| Feature | Blue Diode Laser (450 nm) | Infrared Fiber Laser (1064 nm) |

|---|---|---|

| Absorption in Cu | Extremely high (40–60%) | Very low (3–5%) |

| Weld quality | Extremely stable, low spatter | Highly prone to spatter |

| Thermal load | Low | High |

| Efficiency on metals | Excellent | Poor to moderate |

| Beam focus size | Smaller | Larger |

| Ideal applications | Cu, Au, Al welding, etc. | Steel cutting, engraving, etc. |

| Cost | Slightly higher but decreasing | Mature, lower cost |

While fiber lasers remain unmatched for high-power cutting or welding of steel, blue diode lasers dominate when conductivity and reflectivity become critical factors.

How Blue Diode Lasers Are Manufactured and Scaled

Unlike fiber lasers, which amplify light in a doped fiber, blue diode lasers rely on direct-emitting semiconductor diodes. These diodes are based on gallium nitride (GaN) technology and can be stacked in diode bars or coupled through fibers for higher power output.

The scaling approaches include:

Free-space diode bar stacks

Dense-wavelength beam combining

Fiber-coupled blue diode modules

Multi-emitter arrays

Advances in gallium nitride have made it possible to create compact modules with powers ranging from a few watts to multiple kilowatts.

Market Trends – Why Adoption Is Accelerating

Several industrial megatrends are driving blue diode laser growth:

Rapid expansion of EV battery gigafactories

Increased demand for copper-rich power electronics

Miniaturization of consumer electronics

Growth of high-performance 3D printing

Automation in electronics assembly

Push toward high-efficiency renewable infrastructures

Blue diode lasers directly address the limitations of IR lasers in these industries, making them a crucial enabling technology.

Challenges

Blue lasers are not perfect for every application. Key challenges include:

Lower total power availability compared to IR fiber lasers

Higher cost per watt (though rapidly decreasing)

More sensitivity to optical contamination

Shorter lifetimes in harsh industrial environments (being improved yearly)

Still, ongoing R&D is overcoming many of these issues, making blue diode lasers increasingly competitive on a cost-performance basis.

The Future of Blue Diode Lasers in Manufacturing

The trajectory of blue laser adoption strongly suggests that they will become standard tools in manufacturing environments involving conductive metals. As power scaling continues and costs decline, blue diode lasers will likely expand into:

High-power industrial cutting

Hybrid IR + blue multi-wavelength welding systems

Copper-clad PCB manufacturing

Large-area direct energy deposition (DED)

Precision micro-machining for photonics and sensors

Within a decade, blue diode lasers may become as common in factories as fiber lasers are today.