DBR vs DFB diode lasers is the topic of this blog article. We will do a comparative analysis to help the users decide which technology is more suitable for their applications.

Introduction

Distributed Bragg Reflector (DBR) and Distributed Feedback (DFB) diode lasers are two cornerstone architectures in narrow-linewidth, single-frequency laser design. Both aim to enforce single-mode operation and suppress spurious modes, but they differ in feedback implementation, tuning behavior, and control requirements. Understanding these differences quantitatively is critical for selecting the right laser for telecom, sensing, spectroscopy, or research applications.

This article provides a technical comparison between DBR and DFB lasers, including structure, operating principles, quantitative specifications, and practical applications.

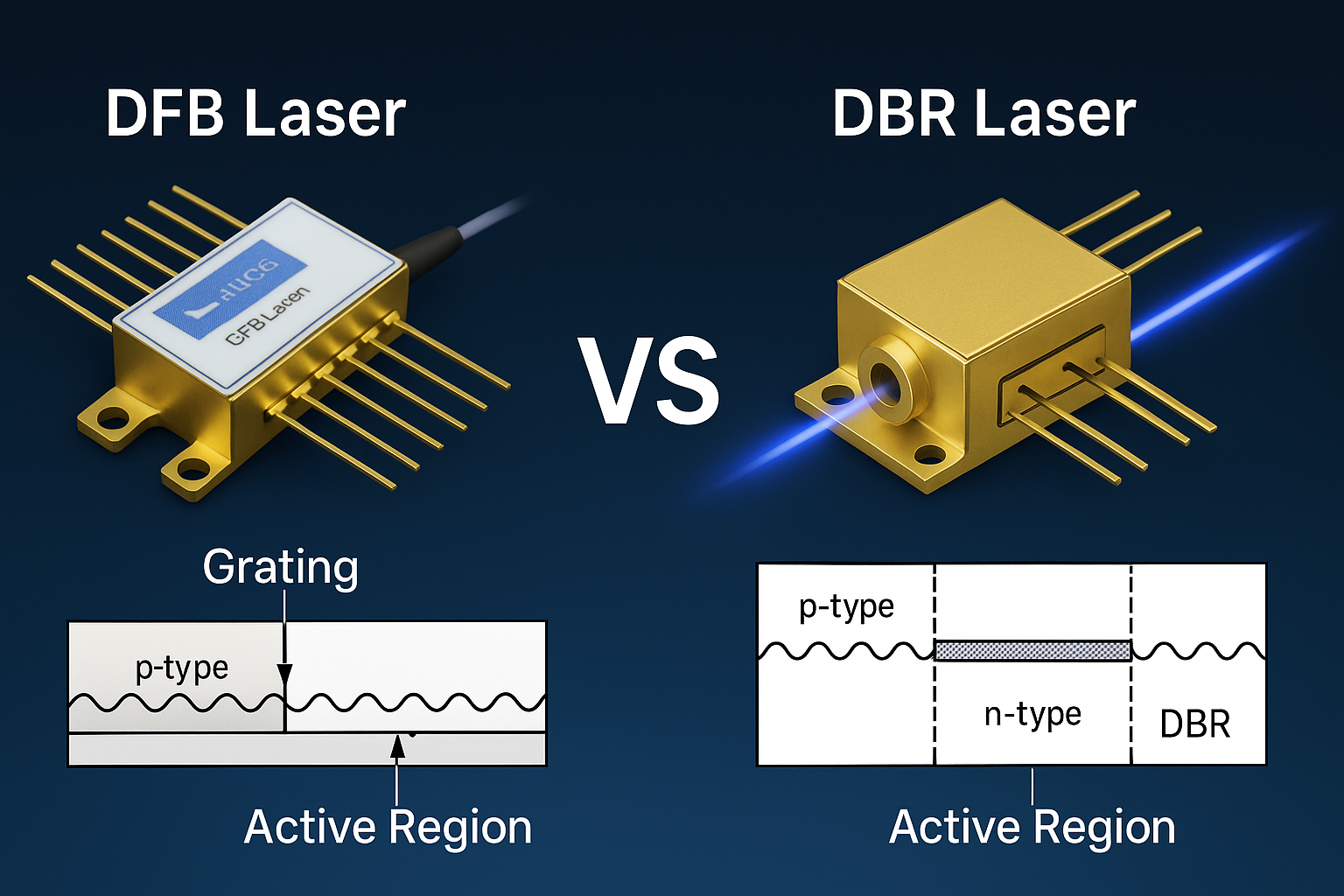

DBR vs DFB Diode Lasers – Architectures

DFB Lasers: Grating Within the Gain Medium

A DFB laser integrates a periodic grating directly into the active gain region. The grating acts as a distributed reflector, favoring a single longitudinal mode. Often, a π-phase shift is included to break degeneracy, ensuring stable single-mode operation.

Because the grating overlaps with the gain, tuning is primarily achieved via current injection or temperature adjustments. The simplicity of a single current-controlled region makes DFB lasers easier to operate and stabilize.

DBR Lasers: Separate Grating and Gain Sections

DBR lasers separate the gain medium from the Bragg grating(s). The gain section generates amplification, while passive grating sections act as wavelength-selective mirrors. Multi-section designs often include phase electrodes to fine-tune the lasing wavelength and minimize mode hops.

This separation allows independent optimization of gain and wavelength selection. However, it requires more sophisticated control and careful thermal management.

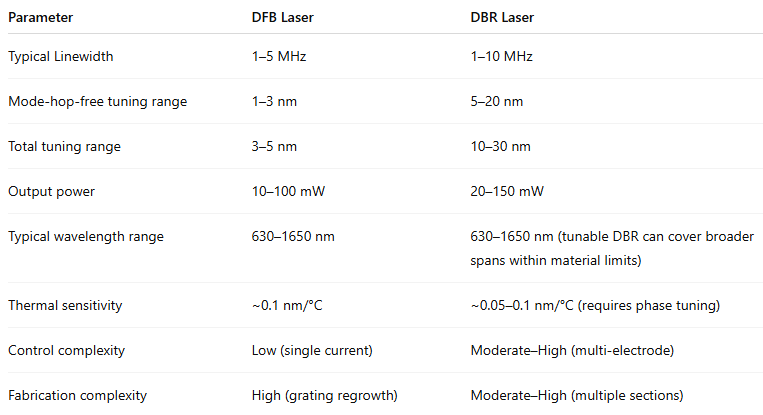

Quantitative Performance Comparison

The table below summarizes typical quantitative differences between DFB and DBR lasers. Note that while the parameters below show typical values, actual products may exceed these performance metrics. For example, DBR may have a power output above 300mW.

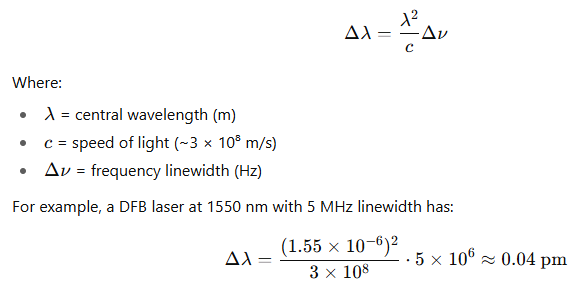

Linewidth is a key metric for coherence and spectral purity.

This narrow linewidth is sufficient for high-resolution spectroscopy, coherent communication, and interferometry. DBR lasers can achieve similar and smaller linewidths depending on design and tuning configuration. For example, DBR lasers operating at 1064nm can have a 500kHz linewidth, which corresponds to 0.0019 pm or 1.9 fm.

Tuning Mechanisms and Ranges

Tuning in DFB lasers is primarily achieved via:

Temperature tuning: ~0.06–0.1 nm/°C

Current tuning: ~0.003–0.01 nm/mA

DBR lasers can tune both the gain section and grating independently. This allows broader total tuning ranges (up to 30 nm), but mode-hop-free ranges are narrower unless phase sections are actively controlled.

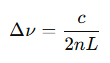

The longitudinal mode spacing can be estimated using:

Where:

n = effective refractive index

L = cavity length

A longer cavity reduces mode spacing, which can affect mode stability and tuning smoothness.

Output Power and Efficiency

DFB lasers: Grating within the gain region can introduce additional losses, limiting achievable power in compact devices. Typical output: 10–100 mW.

DBR lasers: Passive gratings outside the gain medium of DBR lasers allow more active length for amplification, supporting higher power (20–150 mW).

Efficiency depends on facet reflectivity, internal losses, and thermal performance. DBR lasers may require more precise thermal control due to separate grating and gain sections.

Control Complexity

DFB lasers are simpler to operate – one current and temperature loop typically suffice. DBR lasers, especially multi-electrode versions, require coordinated tuning of gain, grating, and phase currents. This allows greater wavelength agility but increases system complexity and cost. In a future blog article we will do a deep dive into the control mechanism of DBR lasers.

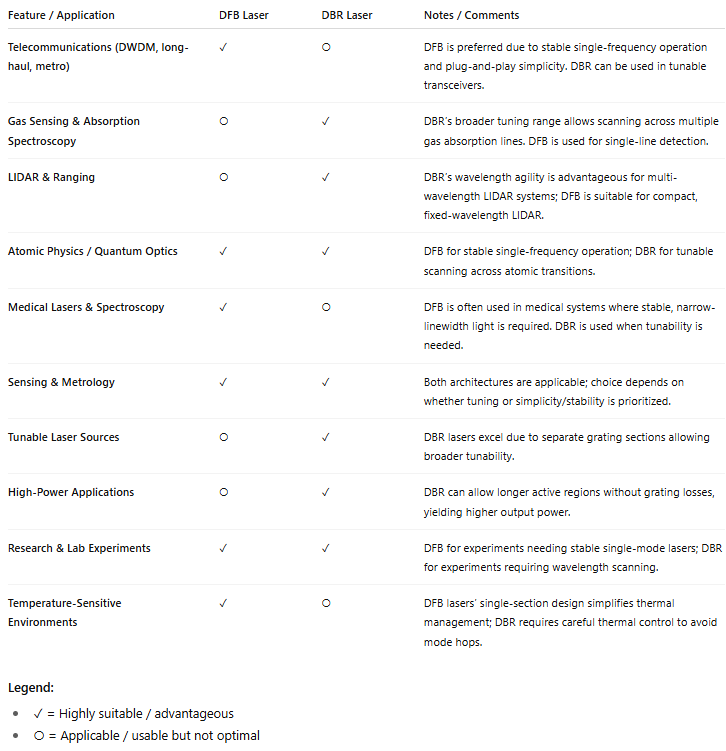

Applications

Telecommunications

DFB: Preferred in dense WDM systems due to plug-and-play stability. Mode-hop-free operation simplifies integration into transceivers.

DBR: Tunable DBR lasers are used in reconfigurable networks or systems requiring multiple wavelengths from a single device.

Spectroscopy and Sensing

DBR: Wider tuning ranges make DBR lasers suitable for gas sensing, absorption spectroscopy, and LIDAR applications.

DFB: Stable single-frequency operation is preferred for compact, low-noise sensors.

Research & Atomic Physics

DFB: Often used when stable, narrow linewidths are more critical than tunability.

DBR: Tuning flexibility is beneficial for scanning across atomic transitions or multi-species detection.

Practical Design Considerations

Thermal Management: DBR requires careful compensation between gain and grating temperatures. DFB is more uniform.

Mode-Hop Avoidance: DBR needs multi-section control to avoid mode hops during tuning. DFB is inherently more stable within its tuning span.

Manufacturability: DFB requires precise grating regrowth. DBR needs multiple sections and electrodes, increasing fabrication complexity.

Bottom line: DFB lasers are excellent for stable, simple, narrow-linewidth applications, while DBR lasers provide broader tunability and higher power potential but require more sophisticated control. Hybrid or external-cavity designs can further enhance performance in demanding applications.

Literature / References

Thorlabs, “Distributed Bragg Reflector (DBR) and Distributed Feedback (DFB) Lasers,” Thorlabs.com

Innolume, “DFB and DBR Laser Products,” innolume.com

Electronics Specifier, “Single-Frequency Laser Diodes – DFB or DBR?”

Wikipedia, “Distributed Feedback Laser,” en.wikipedia.org

Wikipedia, “Distributed Bragg Reflector Laser,” en.wikipedia.org