There exist a plethora of choices when it comes to making a part. Certain manufacturing processes are preferable for different types of parts depending on cost, quality, and quantity needed for any individual part. Today we will provide an introduction to metal manufacturing processes. In each section we present a brief description of the process alongside a related image and common product. The purpose of this article is to be a reference guide which collects links to various educational resources on metal manufacturing processes.

Metal Manufacturing Processes

Metal parts are virtually everywhere, from the device you are reading this from to the iron beams used to hold up bridges. The many methods for making parts from metal include the following:

Forging

Forging is the process wherein hot metal is subject to forced compression in order to obtain the desired shape. Occasionally done entirely by hand, forging involves the heating of metal at high temperatures. In a hot state, the metal receives bends, shapes, and forms using a hammer or die to strike the hot metal. Forging is one of the oldest forms of metal fabrication. Traditionally this process produces swords, knives, and axes due to the strength of forged metals.

An example of forging using a hammer on hot metal. image courtesy of onthepulsenews.com

Heat Treatment

Heat treatment of metal is the process by which the material properties of metal are altered by heating up the metal and cooling it in specific ways. This process includes 4 main types:

- Annealing: which heats up a metal to allow the microstructure to reset inside the part and remove irregularities within the part, after which it cools slowly. The slow cooling allows for more ductility in the crystalline structure of the metal.

- Hardening: this process heats up the metal for the same reason as annealing, however the metal rapidly cools in either water or oil. The result is a harder and much more stable crystalline structure.

- Quenching is a treatment process which cools hot metals rapidly. Often the process involves oil, air, water, or brine depending on desired material properties.

- Stress Relieving: involves the heating of metal to alter its internal structure and then cooling it at a specific rate to reach the desired material properties.

Casting

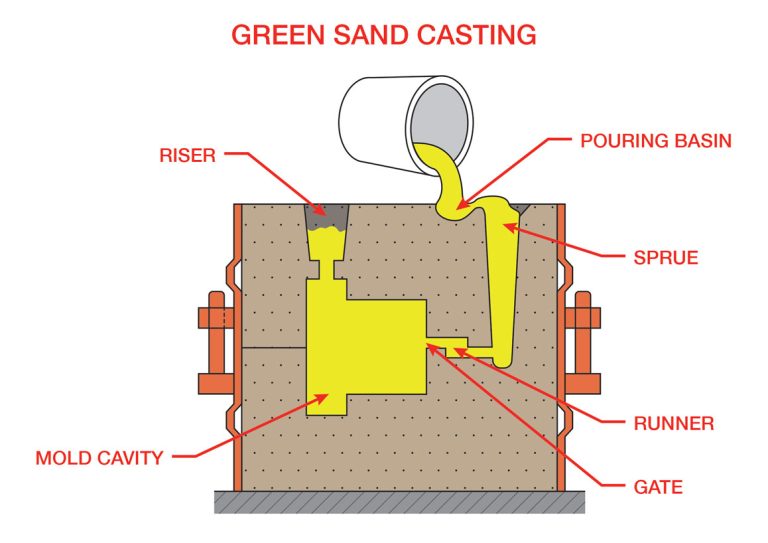

Casting is the process where molten metal is poured into a mold so it can cool and maintain the shape of the mold. Due to the potential of using reusable dies, casting stands as the most popular process for mass produced products. This status is due to the minimal variance in parts cast in the same mold. A notable drawback is high startup costs in developing an adequate mold.

An example of casting using green sand casting. Image courtesy of omnidexcastings.com

Drawing

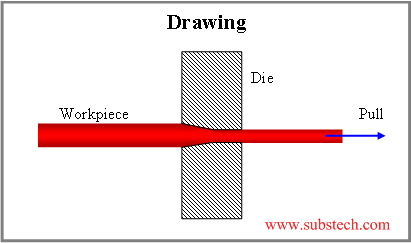

Drawing is the process which uses tensile force to pull metal into a tapered die. The process works at both room temperature as well as elevated temperatures. The drawing process exists for various materials such as metals, plastics, and glass. The result of this process is thinner sheets of metal, which is where most sheets of metal come from.

example of drawing metal by pulling it through a die. Image courtesy of subtech.com

Extrusion

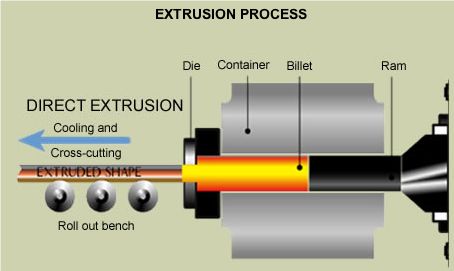

Extrusion is a process in which metal is forced through a die cross section. The cross section of the extruder determines the cross section of the entire forming piece. This process is the most common way of making cylinders of metal.

This shows how metal is extruded through a die. Note that it is a process by which the metal is pushed through an orifice (a.k.a. “Die” in the photo)

Forming

Forming is the process of bending metal at specific points in order to form the desired part. This is achieved with the use of brake presses or with a hammer & clamp. This process is often used in such metals which become reactive with air when melted into a liquid states (which is the reason for not casting these metals). Combinations of the forms in this metal manufacturing processes can create complex objects, such as the well engineered soda can.

Forming can be done in many ways, here we have a small collection of different ways it is achieved. image courtesy of swebend.com

Machining

Machining is a process that can have many forms such as drilling, turning, or milling. This is a subtractive manufacturing technique which means a process which removes material in order to produce the desired part. A very common tool used to perform various material removal processes is a CNC machine. CNC machining is its own subcategory of manufacturing due to the variability of processes that fall under CNC machining. As shown below a popular metal shape made by machining is fine threads on cylinders of metal. We should also note here the entire class of processes under laser machining, which includes laser drilling and laser engraving.

Brass example of a part possible with machining, Image courtesy of china-machining.com

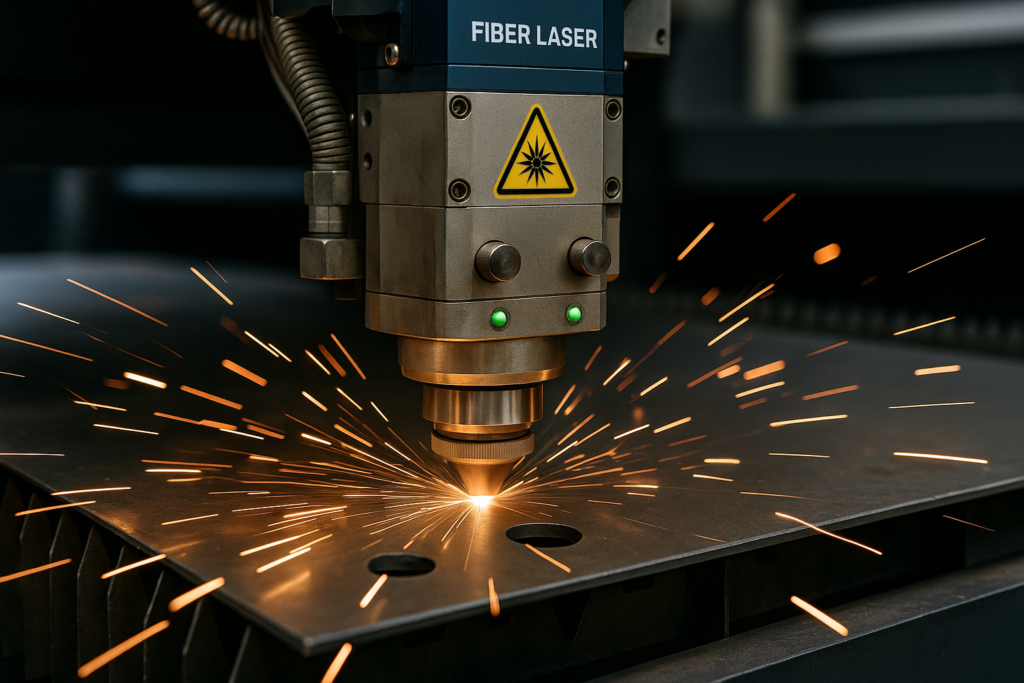

Cutting

Cutting is a foundational subtractive manufacturing process where material is removed from a workpiece to achieve the desired shape or dimensions. In metal fabrication, cutting can be performed using a wide range of tools and technologies, ranging from traditional mechanical shears to advanced methods and tools like laser cutting, CNC waterjet machines, power scissors, and even plasma.

Among these, fiber laser cutting has become a common choice for precision metal fabrication due to its speed, accuracy, and minimal thermal distortion. Manufacturers such as Dowell Laser, with long-standing experience in the field, offer a variety of solutions tailored for different production needs.

High-precision fiber laser cutting process in action. This image shows a fiber laser cutting machine slicing through a metal sheet with pinpoint accuracy. The bright laser beam, visible sparks, and concentrated cutting head highlight the speed and efficiency of the process in modern industrial metal fabrication.

Drilling

Drilling is the process by which a tool removes material at a certain point with a certain depth and diameter. This can be achieved with lasers and metal tool bits.

This is a demonstration of a drill going down on a workpiece. Flutes of metal remain dispersing as a result of their removal from the workpiece.

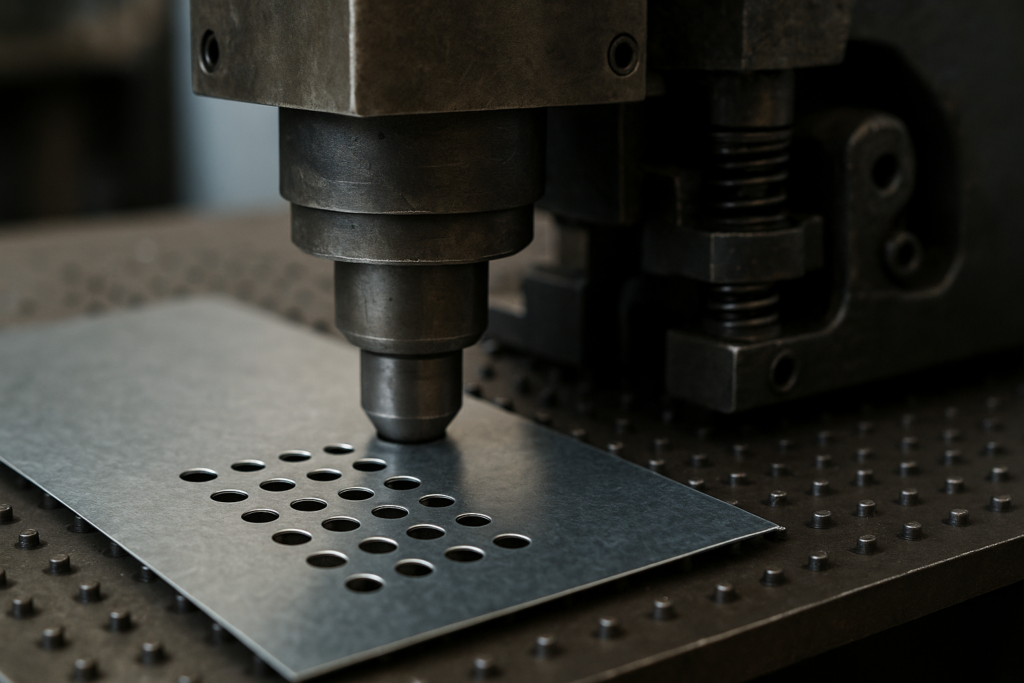

Punching

Punching is the process of creating holes in a piece of metal. Using punch presses, specifically designed tools hit the metal to produce the desired holes. One popular use would be in the realm of making holes for electronics in assemblies with electrical components.

Precision sheet metal punching using a CNC punch press. The image shows a close-up view of a turret punch applying force to perforate a galvanized steel sheet. The machine delivers high-speed, repeatable punches to form accurate holes, commonly used in industrial fabrication for enclosures, brackets, and panels.

Stamping

Stamping is the process by which metal is indented. This process is effective in placing letters, shapes, or images on metal parts. Stamping is often the process of choice to give sheet metal parts the indentations needed to bend along specific seams.

Stamping metal which creates impressions on metal. image courtesy of komaspec.com

Welding

Welding is the process of joining two pieces of metal using heat, pressure, or a combination of both. It remains one of the most commonly used techniques in metalworking due to its reliability and strength, especially when assembling complex structures. Among the various welding methods, laser welding has gained significant popularity for its precision, speed, and minimal thermal distortion.

For applications requiring compact, efficient, and highly accurate solutions, such as jewelry repair, automotive manufacturing, or metal fabrication, laser welding machines have become indispensable. These machines, especially handheld models, offer the flexibility to perform clean, consistent welds even in challenging environments.

Well-known types of welding include: (Direct or Transmission) laser welding, Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW), and Flux Cored Arc Welding (FCAW). You can explore more details about welding techniques and deeper discussions about laser welding in this article on our blog. This process is especially common at joints between metal parts in countless assemblies across industries.

Manual arc welding in progress during metal assembly fabrication. This image shows a welder using a MIG (Gas Metal Arc Welding) torch to fuse two metal workpieces. The welding arc, visible as a bright glow, produces high heat to melt the metal edges.

Conclusion

With all the manufacturing processes shown here it may be daunting to wonder where to start for any particular part. The true first step in part manufacturing is actually material selection, which would be completely dependent on your needs in your manufactured part. Since there are so many part manufacturing processes, knowledge on use and needs of the part make choosing one of these many processes much easier once looking deeper at the pros and cons of each process. Even with the list curated here, it is anything but a subset of all the manufacturing processes that exist for parts. After reading the contents of this article, hopefully you gained more knowledge on metal manufacturing processes.