This article is brought to you by Photodigm Inc. - global leader in laser technologies, offering state of the art Distributed Bragg Reflector laser diodes.

Quantum cascade lasers is the topic of this post, where the reader will find information about the basics of the technology as well as its applications.

iMid-infrared (mid-IR) photonics is rapidly gaining traction across sectors where molecular detection, thermal imaging, and selective spectroscopy are critical. At the core of this revolution is the quantum cascade laser (QCL) — a semiconductor-based light source engineered to emit in the 3 to 25 µm range, where the vibrational and rotational absorption bands of many gases and biomolecules lie. Unlike conventional diode lasers that rely on interband transitions between conduction and valence bands, QCLs exploit intersubband transitions within the conduction band, allowing designers to precisely tailor emission wavelengths via bandgap engineering of quantum well structures.

This architectural flexibility enables narrow-linewidth, high-power sources at custom wavelengths, making QCLs ideal for gas sensing, process monitoring, biomedical diagnostics, and infrared countermeasures. Moreover, the cascading mechanism — where a single electron can generate multiple photons — provides efficient photon generation in compact, rugged, and electrically pumped devices.

As integrated photonics pushes toward miniaturized and chip-scale platforms, QCLs are becoming vital components in optical frequency combs, on-chip spectrometers, and autonomous sensor nodes for next-generation environmental and defense systems. This article provides a comprehensive overview of QCL fundamentals, operating principles, spectral capabilities, and their transformative impact on applied optics and engineering.

1. Introduction

Laser sources in the visible and near-infrared regions have transformed everything from telecommunications to biomedical imaging. Yet, a growing class of applications—especially in chemical sensing, environmental monitoring, and medical diagnostics—demand access to the mid-infrared (mid-IR) spectrum, where most molecular species exhibit strong vibrational absorption features. Detecting gases like methane (CH₄), carbon monoxide (CO), or nitric oxide (NO) with high specificity requires narrow-linewidth, high-power sources in the 3–25 µm range.

Historically, engineers relied on bulky, cryogenically cooled systems or nonlinear frequency conversion to reach these wavelengths. Such solutions often lack the compactness, efficiency, and tunability needed for modern field-deployable instruments. Quantum Cascade Lasers (QCLs) fill this gap with a semiconductor-based approach that offers wavelength agility, high brightness, and room-temperature operation.

Developed in the 1990s, QCLs differ fundamentally from traditional diode lasers. Instead of producing photons via interband transitions between a material’s conduction and valence bands, QCLs use intersubband transitions engineered within quantum wells. This architecture enables engineers to design the emission wavelength by adjusting layer thicknesses, not by changing the material composition. It also allows a single electron to generate multiple photons as it cascades through a series of active regions, hence the name, Quantum Cascade Lasers.

Thanks to this design flexibility, QCLs are now central to a wide range of instruments—from compact trace gas analyzers and medical breath sensors to next-generation infrared countermeasures. In this article, we will explore the physics, design principles, and application landscape of quantum cascade lasers, with a focus on their role in enabling precision sensing and compact mid-IR photonic platforms.

2. Basics of Quantum Cascade Lasers

Quantum cascade lasers (QCLs) operate on a fundamentally different principle than traditional diode lasers. While diode lasers rely on interband transitions—where electrons fall from the conduction band to the valence band—QCLs use intersubband transitions within a single band, typically the conduction band. These transitions occur between energy levels created by quantum wells, thin semiconductor layers that confine electrons in discrete states.

The structure of a QCL is a carefully engineered stack of semiconductor layers, typically composed of III-V materials such as InGaAs and AlInAs grown on an InP substrate. These layers form alternating quantum wells and barriers, creating a one-dimensional potential landscape that guides the behavior of electrons. The thickness of each layer, often controlled with atomic-scale precision using molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD), determines the energy spacing between subbands and, ultimately, the emission wavelength.

3. Intersubband Transitions

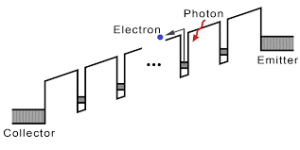

What sets QCLs apart is their cascading architecture. Instead of emitting one photon per electron, like in conventional lasers, a QCL recycles the same electron across multiple gain stages. After emitting a photon in one active region, the electron then tunnels through an injector region into the next stage, where it emits another photon. This process continues through 20 to 100 stages, significantly enhancing efficiency and output power.

The overall gain medium is inherently unipolar—only electrons are involved in the lasing process, unlike bipolar devices that rely on both electrons and holes. This makes QCLs less sensitive to nonradiative recombination and allows them to function across a broader range of operating conditions.

Finally, QCLs typically emit in the mid-IR or terahertz (THz) regions, but their emission wavelength is not tied to the material bandgap. Engineers can define the lasing wavelength anywhere from 3 to over 20 microns simply by adjusting the thicknesses of the quantum wells. This makes QCLs an ideal platform for tailored, application-specific laser sources in spectroscopy, imaging, and sensing.

Illustration showing the tunneling effect of an electron through a series of quantum wells. Courtesy of Wikicommons.

4. Operating Principles of Quantum Cascade Lasers

Building on the principles described earlier, the core of QCL operation lies in its engineered cascade of gain stages, where electrons emit photons repeatedly as they transition between quantized energy levels. Each photon is produced through an intersubband transition in the conduction band, with the emission wavelength set by the engineered thicknesses of the quantum wells.

QCLs support various cavity configurations depending on application needs. Fabry–Pérot (FP) cavities provide broadband emission and are relatively simple to fabricate. For single-mode output, distributed feedback (DFB) gratings introduce a wavelength-selective element, crucial for high-resolution spectroscopy. External cavity (EC) QCLs extend tuning range further using movable gratings or diffraction optics—ideal for multi-species gas detection or scanning applications.

5. Tuning and Spectral Coverage

Quantum cascade lasers offer unmatched spectral flexibility, with emission wavelengths determined by quantum well thickness, not material bandgap. This enables tailored operation from ~3 to over 20 µm using platforms like InGaAs/AlInAs on InP.

Fixed-wavelength QCLs typically use distributed feedback (DFB) gratings to achieve narrow-linewidth, single-mode output. These are essential in applications such as trace gas detection, where molecules like CO₂, CH₄, and NO₂ have sharp absorption lines in the mid-IR.

For broader tunability, external cavity (EC) QCLs integrate a gain chip with a movable grating, enabling mode-hop-free tuning across >100 cm⁻¹. This suits them for multi-species analysis and spectroscopy.

Emerging QCL arrays combine multiple DFB emitters on a chip, providing discrete, electronically switchable wavelengths. These are promising for compact, field-deployable systems.

Engineers optimize thermal stability and cavity design to maintain wavelength precision under variable operating conditions. This spectral control underpins QCLs’ growing role in gas sensing, process monitoring, and security.

6. Applications of Quantum Cascade Lasers

Quantum cascade lasers are redefining how we interact with the mid-infrared spectrum. This region often called the “molecular fingerprint” zone is dense in vibrational absorption features. QCLs offer compact, electrically pumped sources that are tunable, powerful, and wavelength-selective. This make them highly effective across a range of technical applications.

6.1. Gas Sensing and Environmental Monitoring

Perhaps the most mature and commercially adopted application of QCLs is in trace gas detection. Molecules such as methane (CH₄), carbon dioxide (CO₂), nitric oxide (NO), ammonia (NH₃), and sulfur hexafluoride (SF₆) all exhibit strong absorption lines in the 4–12 µm range. QCLs tuned to these lines enable tunable diode laser absorption spectroscopy (TDLAS) or photoacoustic spectroscopy (PAS) at sub-ppm or even ppb sensitivity levels.

These capabilities have been deployed in greenhouse gas monitoring, industrial leak detection, and agricultural process control. Their ruggedness and tunability allow for multi-species sensing from a single device, often integrated into drones, satellites, or stationary platforms.

6.2. Medical Diagnostics

In healthcare, QCLs are enabling non-invasive diagnostics through breath analysis. Human breath contains hundreds of volatile organic compounds (VOCs), many of which are linked to diseases. For example, elevated acetone may indicate diabetes, while nitric oxide is a known marker for asthma and airway inflammation [2]. QCL-based analyzers can detect these biomarkers in real time, offering a platform for early disease detection and patient monitoring without needles or reagents.

Beyond breath analysis, mid-IR QCLs are also being explored for tissue imaging and optical biopsy, leveraging the spectral contrast between healthy and diseased tissues in vibrational modes of lipids, proteins, and water.

6.3. Security, Defense, and Aerospace

QCLs offer compact, robust sources for infrared countermeasures (IRCM), where directed IR beams confuse heat-seeking missiles. Their ability to emit in specific, tunable mid-IR bands makes them ideal for spoofing advanced tracking systems.

Additionally, QCLs are being integrated into field-deployable chemical sensors for detecting explosives, chemical warfare agents, and toxic industrial compounds. With their small footprint and high brightness, QCLs are well suited for deployment in unmanned aerial vehicles (UAVs) and handheld analyzers.

6.4. Process Control and Materials Analysis

In industry, QCLs are transforming process analytical technology (PAT). In combustion systems, QCLs monitor exhaust gases in real time to improve efficiency and reduce emissions. While in pharmaceutical manufacturing, they enable in-line monitoring of reaction endpoints, solvent levels, and crystal forms without halting production.

Materials scientists also use QCLs in mid-IR imaging and spectroscopy to analyze polymer blends, identify contaminants, or study thin films. Compared to FTIR systems, QCLs offer higher brightness, faster scanning, and better spatial resolution when paired with focal plane arrays.

7. Challenges in Quantum Cascade Laser Development and Deployment

Despite their remarkable performance and flexibility, quantum cascade lasers have their own limitations. Their broader adoption, especially in commercial and field-deployable systems, still depends on overcoming several engineering and manufacturing challenges.

7.1. Thermal Management

One of the most persistent issues is thermal loading. Each photon emitted in a QCL is accompanied by non-radiative transitions that generate heat. This is especially problematic in continuous-wave (CW) operation or high-power pulsed modes, where active cooling is often required to maintain stable output and prevent thermal rollover [1]. Poor thermal design can shift the gain spectrum, reduce wall-plug efficiency, and compromise long-term reliability.

Efforts to mitigate this include the use of high thermal conductivity substrates, advanced heat sink geometries, and short cavity lengths to reduce power density. As a result, room-temperature CW operation is now feasible in many designs, but often at the cost of reduced power output or narrower tuning range.

7.2. Fabrication Complexity and Cost

Unlike conventional diode lasers, QCLs rely on precise epitaxial growth of dozens of quantum wells and barriers—often totaling over 1,000 layers with nanometer-scale accuracy. This requires molecular beam epitaxy (MBE) or metal-organic chemical vapor deposition (MOCVD) systems with tight process control and high material quality [2].

Such complexity increases manufacturing cost and limits economies of scale. Although production yields have improved, particularly for shorter wavelengths (3–6 µm), fabricating high-performance devices in the 8–12 µm range remains challenging.

7.3. Beam Quality and Mode Control

In some applications, particularly spectroscopy or directed energy, beam quality matters as much as output power. QCLs typically exhibit divergent, multi-lobed beam profiles due to their narrow ridge waveguides and high index contrast. Achieving single-mode operation or near-diffraction-limited beams often requires careful cavity design and external beam-shaping optics [3].

Moreover, mode-hopping or spectral drift under thermal or current fluctuations can limit QCL usability in precision applications without active stabilization.

8. Conclusion

Quantum cascade lasers have emerged as one of the most versatile and powerful sources of mid-infrared light available to engineers and scientists. Their fundamentally different emission mechanism—based on intersubband transitions in engineered quantum wells—allows for a degree of spectral control and design flexibility unmatched by traditional diode lasers.

From ultra-sensitive gas detection and non-invasive medical diagnostics to aerospace defense systems and industrial process monitoring, QCLs are enabling applications once considered impractical or impossible. Their compact form factor, tunability, and wavelength specificity are unlocking new frontiers in precision sensing and spectroscopy.

Yet, challenges remain. Efficient thermal management, complex fabrication, and spectral stability continue to shape the boundaries of practical QCL deployment. Fortunately, advances in epitaxial growth, packaging, and integrated photonics are rapidly addressing these hurdles.

For engineers working at the intersection of optics, sensing, and materials, QCLs are not just a niche innovation—they are a foundational tool. Mastering their capabilities today opens the door to designing smarter, faster, and more selective systems across virtually every high-tech industry.

9. References

- Capasso, Federico, et al. “New frontiers in quantum cascade lasers and applications.” IEEE Journal of selected topics in quantum electronics 6.6 (2002): 931-947.

- Rauter, Patrick, and Federico Capasso. “Multi‐wavelength quantum cascade laser arrays.” Laser & Photonics Reviews 9.5 (2015): 452-477.

- Faist, Jérôme, et al. “Quantum cascade laser frequency combs.” Nanophotonics 5.2 (2016): 272-291.

- Childs, David TD, et al. “Sensitivity advantage of QCL tunable-laser mid-infrared spectroscopy over FTIR spectroscopy.” Applied Spectroscopy Reviews 50.10 (2015): 822-839.

- Vitiello, Miriam Serena, and Alessandro Tredicucci. “Tunable emission in THz quantum cascade lasers.” IEEE Transactions on Terahertz Science and Technology 1.1 (2011): 76-84.

- Patel, C. Kumar N. “High power infrared QCLs: advances and applications.” Quantum Sensing and Nanophotonic Devices IX 8268 (2012): 17-29.