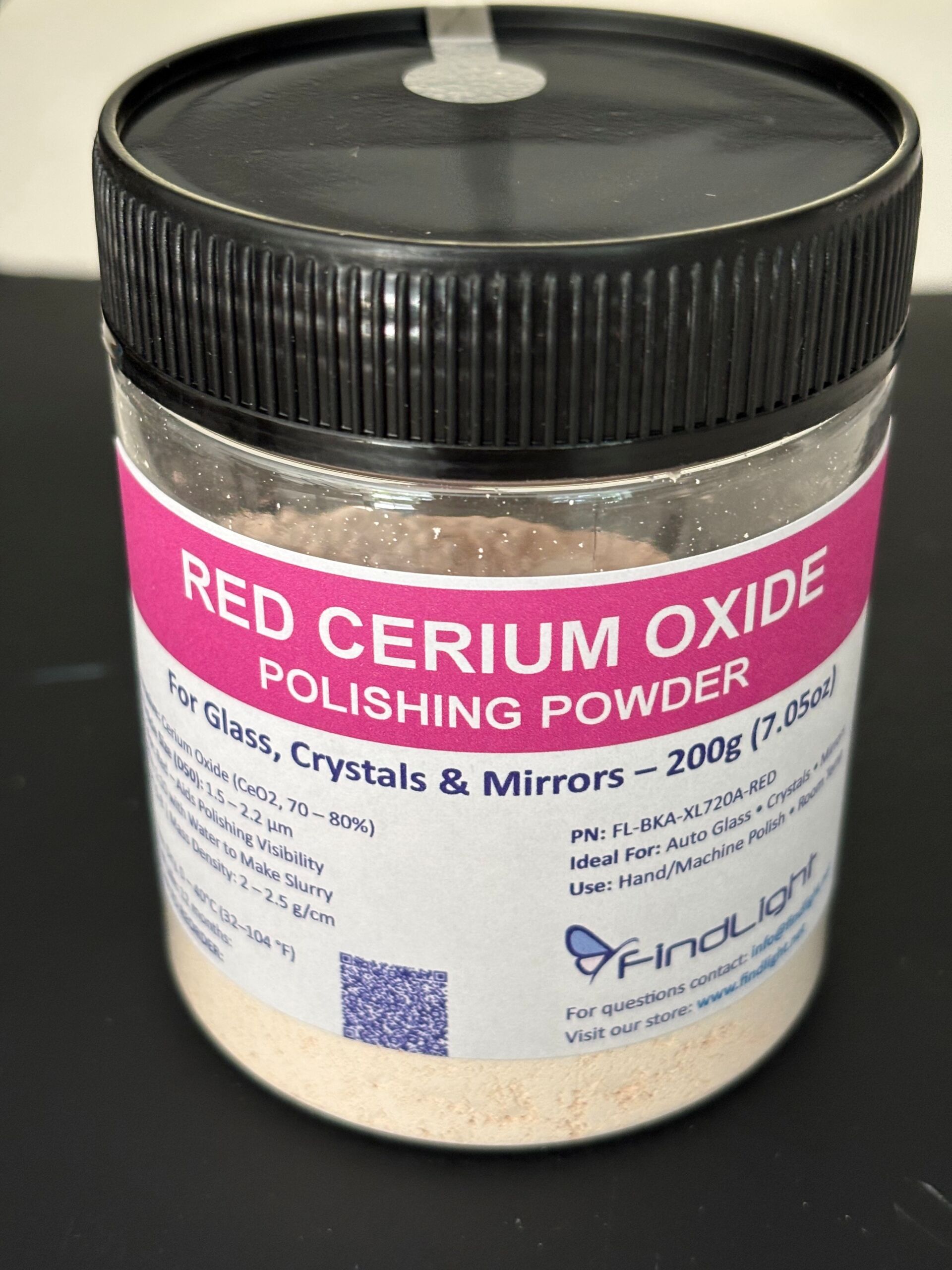

This blog article is about cerium oxide polishing powder for glass, crystal and mirror polishing. The sponsor of this article is FindLight Essentials.

Introduction

Cerium oxide polishing powder is one of the most effective materials for restoring clarity and shine to glass and crystal surfaces. While high-purity powders are reserved for precision optics, lower-grade cerium oxide is widely used for automotive glass repair, DIY projects, decorative crystal restoration, and other everyday applications. Its combination of chemical reactivity and mechanical abrasiveness makes it ideal for removing scratches, haze, and watermarks while preserving surface integrity.

This comprehensive guide explains how cerium oxide works, what grades are available, how to select the right powder, and practical techniques for achieving professional-quality results on windshields, crystal, and other glass surfaces.

What Is Cerium Oxide Polishing Powder?

Cerium oxide (CeO₂) is a rare-earth oxide that functions as a chemical-mechanical polishing (CMP) agent. When applied as a slurry with water, cerium oxide particles interact with silica in the glass surface. This dual action softens microscopic imperfections, allowing abrasives to remove them efficiently while minimizing the risk of deep scratches.

Lower-grade cerium oxide powders are typically beige, pink (red), or light brown and may contain small amounts of lanthanum or praseodymium oxides. These powders are perfectly suitable for windshields, decorative glass, and crystal, providing excellent performance at a fraction of the cost of optical-grade materials.

Why Cerium Oxide Is Preferred for Glass and Crystal

Cerium oxide stands out from other abrasives because it provides both chemical and mechanical polishing. Compared to alternatives like aluminum oxide, silicon carbide, or diamond paste, cerium oxide offers several advantages:

Balanced abrasiveness: Polishes without over-cutting or creating micro-scratches.

Chemical reactivity: Forms a hydrated surface layer on silica, improving efficiency and finish.

Versatility: Works on soda-lime glass, borosilicate glass, lead crystal, and tempered glass.

Cost-effectiveness: Lower grades are affordable and widely available for commercial and DIY applications.

This combination makes cerium oxide ideal for applications that require clarity and shine but do not demand the nanometer-scale precision of optical-grade polishing.

Grades of Cerium Oxide Polishing Powder

Cerium oxide powders are classified based on purity, particle size, and intended application:

High-purity (≥99% CeO₂): Reserved for optical lenses, prisms, and semiconductor components.

Medium-purity (80–95% CeO₂): Common for automotive glass repair and decorative crystal polishing.

Standard grade (60–80% CeO₂): Affordable and sufficient for DIY use and general glass maintenance.

Particle size is equally important: fine powders (0.5–2 micron) produce a smooth, high-gloss finish, while coarser powders (2–4 microns) remove scratches faster but may leave haze if not followed by a finer polish.

Cerium Oxide for Precision Optics Manufacturing. Powders of this grade are typically white or light creamy color, while the lower-grade powders for windshield and glass polishing are pink (red).

How Cerium Oxide Polishing Works

Polishing with cerium oxide is both a mechanical and chemical process:

Slurry formation: Powder is mixed with distilled water to form a creamy consistency.

Application: The slurry is applied to the glass or crystal surface using a felt or foam pad.

Polishing action: Friction generates heat, accelerating the chemical reaction between cerium ions and silica.

Surface smoothing: The chemical reaction softens microscopic imperfections, which are removed by abrasive action, leaving a clear, defect-free surface.

This dual mechanism is what allows cerium oxide to outperform many purely mechanical abrasives in terms of both speed and finish quality.

Applications of Cerium Oxide Polishing Powder

Automotive Windshield Repair

Auto glass frequently suffers from scratches caused by wipers, road debris, or environmental wear. Cerium oxide polishing allows repair technicians to restore clarity and optical quality without replacing the windshield. Rotary polishers or hand-held drill attachments are commonly used with 1–3 micron powders providing an optimal balance between cutting power and finish.

Decorative Glass and Crystal

Crystal vases, chandeliers, and glass figurines can lose their brilliance due to surface scratches and haze. Cerium oxide effectively restores clarity without damaging delicate shapes or edges. For smaller items, hand polishing with a felt pad is sufficient; for larger surfaces, rotary tools or polishing wheels improve efficiency.

DIY and Hobbyist Applications

Hobbyists use cerium oxide to polish aquarium glass, shower doors, mirrors, and even watch crystals. Because the powder is non-toxic, easy to mix, and effective, it’s ideal for home use. Careful slurry preparation and moderate polishing speed ensure excellent results without professional equipment.

Marine and Aviation Glass

Boat windows, cockpit canopies, and other transparent surfaces exposed to the elements benefit from cerium oxide polishing. It removes water spots, oxidation, and minor scratches, maintaining visibility and aesthetic appeal.

How to Select the Right Cerium Oxide Powder

When choosing a cerium oxide polishing powder for non-precision applications, consider:

Particle size: Smaller particles provide a finer finish; larger particles polish scratches faster.

Purity: Medium-grade powders (80–95% CeO₂) are sufficient for windshields, decorative glass, and crystal.

Color and composition: Minor rare-earth oxides do not significantly affect performance but can indicate lower cost grades.

Packaging and quantity: Bulk packs (500 g to 25 kg) are cost-effective for workshops, while small consumer packs suit hobbyists.

Step-by-Step Polishing Guide

Prepare the slurry: Mix cerium oxide with distilled water to a thin cream consistency. Stir frequently.

Apply evenly: Spread the slurry over the surface using a felt or foam pad.

Maintain wet conditions: Keep the surface moist during polishing to prevent heat damage.

Use moderate pressure: Let the powder do the work; excessive force may cause uneven finish.

Rinse and inspect: Remove all residue and evaluate results, repeating as necessary for deeper scratches.

Professional auto glass shops may integrate water-cooled rotary polishers or temperature monitoring, while hobbyists can achieve excellent results with a hand-held drill and felt pad.

Advantages Over Other Polishing Agents

While alternatives like aluminum oxide, silicon carbide, and diamond paste exist, cerium oxide’s chemical-mechanical action sets it apart:

Diamond paste: Too aggressive for most glass; risks distortion.

Aluminum oxide: Purely mechanical, slower results, may leave micro-scratches.

Silicon carbide: Too harsh, likely to create haze.

Cerium oxide achieves a high-gloss finish efficiently while minimizing surface damage.

Cost and Availability

Cerium oxide powders for general glass polishing are widely available online and through industrial distributors. Prices range from $20 to $80 per pound for medium-grade powders, making them accessible for both commercial and DIY use. Bulk orders reduce cost per kilogram, which is advantageous for auto glass repair shops or large-scale crystal polishing operations.

High-purity optical-grade powders are significantly more expensive (often five to ten times the cost) and are unnecessary for non-precision applications.

Safety and Environmental Considerations

While cerium oxide is generally safe, precautions include:

Wearing gloves, goggles, and a dust mask.

Avoiding inhalation of dry powder.

Properly disposing of slurry to prevent environmental contamination.

Storing powders in sealed containers to prevent moisture absorption.

Environmentally, cerium oxide is safer than many chemical polishing agents. Waste slurry is typically non-hazardous but should be disposed of according to local regulations.

Market Trends

Demand for cerium oxide polishing powders is growing in the automotive, DIY, and decorative glass markets. As more consumers and repair shops opt to refurbish rather than replace glass, cost-effective medium-grade powders are increasingly popular. China remains the largest producer, but North American and European distributors are expanding to meet DIY and professional demand.

Conclusion

Cerium oxide polishing powder is a versatile, cost-effective solution for restoring glass and crystal surfaces. Its chemical-mechanical action removes scratches, haze, and surface imperfections while producing a clear, high-gloss finish. For applications like windshield repair, decorative crystal polishing, and DIY glass restoration, medium-grade powders offer the ideal balance of performance and affordability.

By selecting the appropriate particle size and purity, preparing an effective slurry, and following proper polishing techniques, both professionals and hobbyists can achieve exceptional results. Cerium oxide remains the industry standard for everyday glass and crystal polishing, providing clarity, brilliance, and durability for a wide range of applications.