Failure Analysis of LEDs, lasers and their driving circuitry

Description

LED and Luminaire Failure Analysis

Typical applications:

Root Cause Failure Analysis

Technology Evaluation

Supplier Qualification

Quality Documentation

Non-conformance Verification

Reliability Qualification to LM-79 and LM-80

Technology Cloning

Destructive Physical Analysis (DPA)

Intellectual Property Violation Counterfeit Detection

Failure Analysis of LEDs, lasers and their driving circuitry

Specifications |

|

|---|---|

| Type Of Service: | Other |

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Canada

-

Sold by:

-

On FindLight:

since 2020

Frequently Asked Questions

The purpose of the Failure Analysis is to determine the failure mode and root cause of failure of LEDs, lasers, and their driving circuitry.

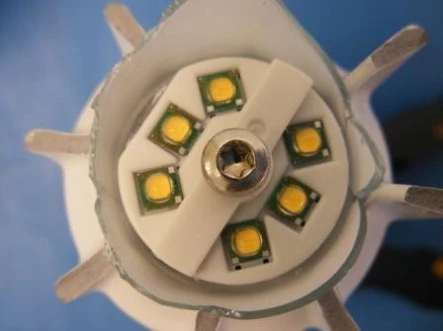

The typical applications of the Failure Analysis include root cause failure analysis, technology evaluation, supplier qualification, quality documentation, non-conformance verification, reliability qualification to LM-79 and LM-80, technology cloning, destructive physical analysis (DPA), intellectual property violation, and counterfeit detection.

The analysis methods used in the Failure Analysis include optical inspection, pin test, cross-section analysis, and scanning electron microscopy (SEM).

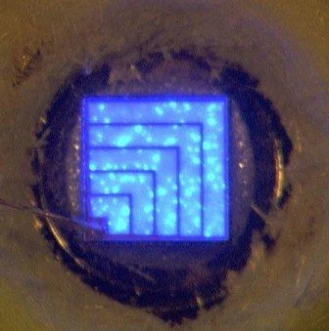

The analysis found that the failed and intermittent LED's had temperature-dependent intermittent open circuits but no apparent damage at the semiconductor device level. There was a delamination of the clear epoxy molding compound from the inner surfaces of the metal reflector of the leadframe, and the die was lifted from the die attach glue line. There was no evidence of wirebond failure.

The electrical characterization confirmed that the operating voltage at a fixed current drops with temperature, suggesting that without active current regulation, these devices may run at higher currents and temperatures than intended or expected.

You May Also Like

Don’t have an account?

Please consider registering

NOTE: It may take up to 10 min to receive the registration verification link. For immediate assistance please use the “GUEST” option above.

Your inquiry has been received

by adding a password

Benefits of having an account:

- Save time on filling future request forms

- Track your prior Requests

- Save favorite products in your account

- Choose your contact preferences

- If you change your mind later, you may close you account with 1 click

The Leading Photonics Marketplace

Within 3-10 minutes you will receive an email with a validation link to activate your account.

If you don't receive the confirmation link soon, please let us know at contact@findlight.net

Useful quick links