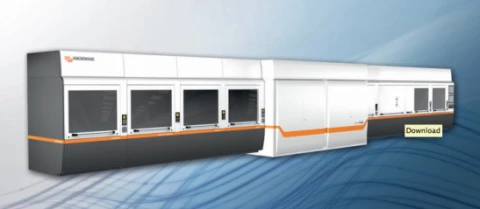

microFLEX Roll-to-Roll Laser Processing Platform

Description

microFLEX Roll-to-Roll Laser Processing Platform

Specifications |

|

|---|---|

| Processes: | Ablation, Cutting |

| Materials: | Metals, Polimers |

| Laser Type: | Fiber |

| Laser Safety: | Not classified |

| Work Area X: | 300 mm |

| Work Area Y: | 300 mm |

| Number Of Axes: | 3-Axis |

| Beam Delivery: | Galvo Scanner |

| Features And Options: | Integrated, Multi-Axis |

Features

- Laser processing on-the-fly or in step and repeat mode

- Integration of different laser sources and wavelengths

- Various optical setups, e.g. galvo scanner, fixed optics, and line beam set-up

- Highest precision in web control: down to ± 1 μm tracking error

- Machining under ambient conditions, inert gas atmosphere or vacuum

- User-friendly, flexible system control including MES

- Roll-to-roll or roll-to-sheet configurations

Applications

- Laser structuring

- Laser patterning

- Laser cutting

- Printing and coating

- Laser annealing

- Laser lift-off

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

Germany

-

Sold by:

-

On FindLight:

External Vendor

Claim 3D Micromac Page to edit and add data

Frequently Asked Questions

The microFLEX Roll-to-Roll Laser Processing Platform is ideal for several applications, including laser structuring, laser patterning, laser cutting, printing and coating, laser annealing, and laser lift-off.

The microFLEX Roll-to-Roll Laser Processing Platform offers several benefits, including high-precision laser processing, high throughput and efficiency, in-situ quality control, and use of different micro-environments. It is highly versatile and can be customized for industrial mass production, pilot lines, and applied research.

The microFLEX Roll-to-Roll Laser Processing Platform has several features, including laser processing on-the-fly or in step and repeat mode, integration of different laser sources and wavelengths, various optical setups, highest precision in web control, machining under ambient conditions, inert gas atmosphere or vacuum, and user-friendly, flexible system control including MES.

The microFLEX Roll-to-Roll Laser Processing Platform is a highly versatile production platform that combines high-precision laser processing with cleaning, coating, printing, and packaging technologies as well as inline quality control. It is used for the manufacturing of flexible thin films in photovoltaics, electronics, medical devices, displays, and semiconductors.

The microFLEX Roll-to-Roll Laser Processing Platform can handle various substrates, material thicknesses, and types such as polymer films, stainless steel, and thin glass.