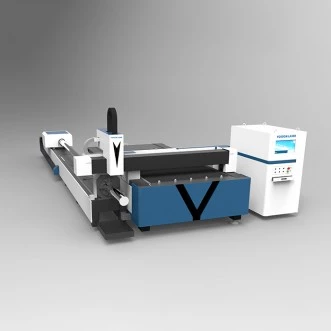

3000W Fiber laser Equipment Carbon Steel Stainless Steel Sheets Copper Tube Laser Cutting Machine

Description

Laser cutting is an advanced processing method used in material processing. The laser cutting machine produced by our company is equipped with precision linear guides and high-precision rack and pinion transmission mechanism. It is a precision CNC laser cutting machine assembled through a professional laser cutting CNC system.

It is an integrated high-tech product consist of laser cutting, precision machinery, CNC technology, and other parts . It is mainly used for cutting and forming carbon steel, stainless steel, carbon fibers, alloy materials, galvanized plates, electrolytic plates, copper plates, aluminum plates and other materials. It has the characteristics of high precision, high efficiency, and high cost performance.

3000W Fiber laser Equipment Carbon Steel Stainless Steel Sheets Copper Tube Laser Cutting Machine

Specifications |

|

|---|---|

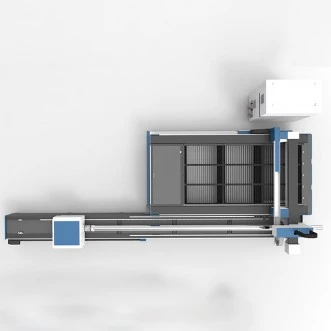

| Platform Type: | Gantry |

| Materials: | Steel, Iron, Aluminum, Brass, Copper |

| Laser Type: | Fiber Laser |

| Max Laser Output Power: | 3000 W |

| Processing Length (X): | 13000 mm |

| Processing Length (Y): | 2500 mm |

| Max Processing Length (Z): | 100 mm |

| Max Processing Speed: | 1667 mm/sec |

| Positioning Accuracy: | 3 um |

| Repeatability: | 2 um |

| Laser Medium: | Mirror-doped double-clad fiber |

| Cooling: | Water cooling |

| Electrical Requirement: | 380V-50Hz/60Hz |

| Laser Source: | MAX/Raycus/IPG |

Features

Advantages of laser cutting machine in processing:

1. Good cutting quality, reducing labor costs

The laser cutting machine uses the characteristics of laser non-contact processing, no damage to the workpiece, no extrusion deformation to the cut product, the processed product is of good quality, no burrs, no manual polishing, saves unnecessary processing procedures, and optimizes workers Labor intensity.

2. Save mold investment and reduce production costs

The laser cutting machine can directly produce various hardware workpieces without molds, mold consumption, and mold maintenance and replacement. It can save a lot of molds, save processing costs, and reduce production costs. It is especially suitable for processing large products.

3. High precision, effectively improve production efficiency

The "cut-" alternative process appears in the laser cutting process, with precise features, flexible, efficient, and effective processing of complex parts. Only the cutting graphics need to be imported into the control system, and the size cutting can be set, which helps to shorten the product processing and The production cycle directly and effectively improves labor productivity.

4. Fast cutting speed and optimized working environment

The laser cutting machine cuts quickly. When the equipment is stable, low noise, no dust, it will not produce chemicals that are harmful to the human body and the environment. It is a sweet thing to protect the operator, ensure that the production site is tidy, and later reduce investment, reduce pollution, and help The optimized working environment promoted by hardware companies is in line with the trend of environmental protection.

5. Low maintenance cost and high cost performance

The maintenance of mechanical products is very expensive, and the laser cutting machine has stable performance, sturdiness and durability, can work continuously, is not easy to be damaged, and has a great advantage in later maintenance costs.

For pricing, technical or any other questions please contact the supplier

- No registration required

- No markups, no fees

- Direct contact with supplier

-

Ships from:

China

-

Sold by:

-

On FindLight:

since 2021

Frequently Asked Questions

The laser cutting machine can cut carbon steel, stainless steel, carbon fibers, alloy materials, galvanized plates, electrolytic plates, copper plates, aluminum plates, and other materials.

The advantages of using a laser cutting machine include good cutting quality, reduced labor costs, savings on mold investment and production costs, high precision, improved production efficiency, fast cutting speed, optimized working environment, low maintenance cost, and high cost performance.

No, the laser cutting machine can directly produce various hardware workpieces without the need for molds, saving on mold consumption, maintenance, and replacement costs.

Yes, the laser cutting machine operates with low noise, no dust, and does not produce harmful chemicals, making it environmentally friendly and promoting an optimized working environment.

The laser cutting machine has stable performance, sturdiness, and durability. It can work continuously and is not easily damaged, resulting in low maintenance costs and high cost performance.